In a multitude of technologies, which solution fits your CO2 streams best?

Guiding organisations from strategy to implementation

Reducing CO2 emissions is an important element of environmental and sustainability strategies for many companies. However, there is no “one size fits all” strategy.

Based on techno-economic analysis, VITO helps organizations of all sizes to identify and implement the solutions that best fit their carbon streams, budgets and ambitions.

How to capture CO2 in a cheaper and more effective way?

One of the most significant barriers to wide-scale industrial deployment of CO2 capture is the high energy demand and cost associated with the CO2 capture process. Technological developments are believed to play an important role in reducing the CCUS costs. VITO is developing innovative solid sorbents to capture CO2 in packed bed configurations as a more energy efficient alternative to current liquid phase, mostly amine-based absorption processes. The solution to reduce the CO2 capture cost is to control the shape of the sorbent to ensure the CO2 sorption capacity is optimally used and the air / flue gas can flow easily through the structure when scaled up.

In another approach, electrochemical processes are coupled to liquid phase scrubbing with alkaline solutions, by which CO2 is concentrated and liberated or converted in-situ. To attain this, VITO develops electrocatalysts, membranes and novel electrolyser concepts.

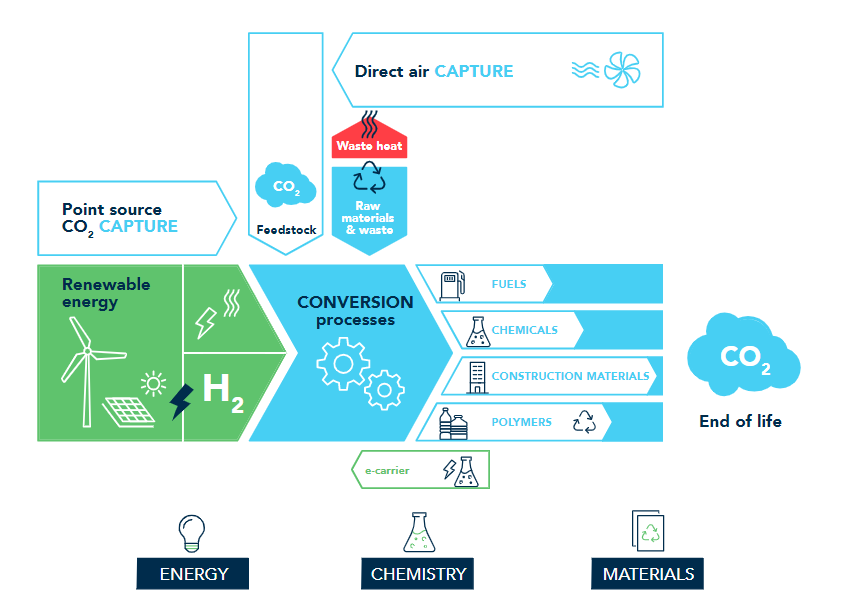

What to do with CO2?

You can capture and store away CO2 in the underground but you can also use it to produce economically valuable products:

- building materials with a low or carbon negative footprint using carbonation

- non-fossil fuel by having CO2 react with hydrogen in a controlled manner or directly via CO2 electrolysis in aqueous environment

- chemicals or their intermediates, such as an alternative to ethanol, methanol, syngas, ethylene, …

- polymers and plastics

“We already have CO2-based products that fit perfectly into the existing market. Products where the consumer contributes to the fight against climate change, simply by using them.” Metin Bulut, CCU expert at VITO.

An example: first carbon negative footpath

In Ghent you can walk on the first carbon negative footpath. The foothpath in the Leeuwstraat is constructed using Carbstone paving stones.

“Carbstone paving stones are created by allowing steel slag, a residual product from the steel industry, to react with CO2 to create a range of products with the same technical properties as conventional concrete products. As this method doesn’t use cement but CO2 as a reactive binder, this drastically lowers the environmental impact of building materials”. Mieke Quaghebeur, CCU expert at VITO.

Read more on CCU

From greenhouse gas to raw material: carbon capture & utilisation as a weapon against global warming