Lab membrane filtration units: solvent and water

At VITO we offer a range of solvent membrane filtration equipement for both small and large labs, which uses organic solvent based pressure-driven membrane filtration. The units can be used for a wide range of applications such as concentration, purification and solvent swap of APIs or clean-up of viscous waste oils, plastic oils, lignin oils, etc.

What can you use it for?

- Concentration, purification and fractionation of target compounds from solvent-based process streams (e.g. APIs, natural products)

- Recovery of spent solvents from process and waste streams

- Recovery of homogeneous catalysts from post-reaction mixtures

- Upstream/downstream clean-up of oils (e.g., lignin oil, used cooking oil, used lubricant oil, plastic oil)

Large lab units

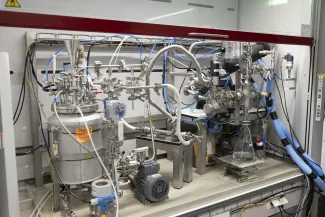

NF1

Technical features

- Flexible larger cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 120°C – 35 bar (316 L, Kalrez)

- Multi-channel ceramic membranes, 2540-spiral-wound elements and tubular polymeric membranes

- Feed tank of 5 L, min. working volume 1 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

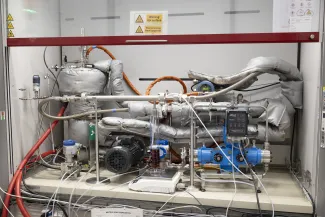

NF9

Technical features

- Flexible larger cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 120°C – 35 bar (316 L, Kalrez)

- Multi-channel ceramic membranes, 2540-spiral-wound elements and tubular polymeric membranes

- Feed tank of 5 L, min. working volume 1 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

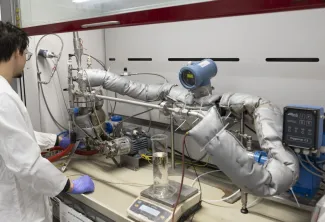

NF8

Technical features

- Flexible larger cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 120°C – 35 bar (316 L, Kalrez)

- Multi-channel ceramic membranes, 2540-spiral-wound elements and tubular polymeric membranes

- Feed tank of 5 L, min. working volume 1 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Backwash/backflush unit allowing for in situ mechanical membrane cleaning

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

Small lab units

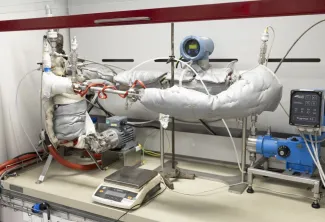

NF3

Technical features

- Flexible smaller cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 80°C – 35 bar (316 L, Kalrez)

- Single-channel ceramic membranes, flat sheet and tubular polymeric membranes

- Feed tank of 1 L, min. working volume 300 mL

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

NF4

Technical features

- Flexible smaller cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 100°C – 35 bar (316 L, Kalrez)

- Single-channel ceramic membranes, flat sheet and tubular polymeric membranes

- Feed tank of 1 L, min. working volume 300 mL

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

NF5

Technical features:

- Flexible smaller cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 120°C – 35 bar (316 L, Kalrez)

- Single-channel ceramic membranes, flat sheet and tubular polymeric membranes

- Feed tank of 1 L, min. working volume 300 mL

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

NF6

Technical features

- Flexible smaller cross-flow lab unit for solvent (and water)-based pressure-driven membrane filtration (UF/OSUF, NF/OSN, RO/OSRO)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 120°C – 35 bar (316 L, Kalrez)

- Single-channel ceramic membranes, flat sheet and tubular polymeric membranes

- Feed tank of 1 L, min. working volume 300 mL

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Non-food grade (open) installation, applicable for food/pharma applications through disinfection protocol

Pervaporation unit & membrane contactors

Pervaporation

Technical features:

- Flexible cross-flow lab unit (316 L, Kalrez)

- Desk-top installation mounted in fume hood, semi-mobile

- Max. 150°C – 30 bar

- Single-channel ceramic/zeolite membranes, flat sheet polymeric membranes

- Feed tank of 5 L, min. working volume 1 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

Membrane contactors: membrane distillation

Technical features:

- Flexible lab-scale MD unit which can be used in DCMD, AGMD and VMD configuration

- Flat-sheet modules for polymeric membranes (0,033 m² and 0,011 m²)

- Feed tank of 5L, minimum working volume of 1L

- Max temperature: 95°C

- Fully instrumented with real time process monitoring and data acquisition

Membrane contactors: membrane extraction

Technical features:

- Flexible lab-scale ME unit for membrane-based solvent and reactive extraction

- Desk-top installation mounted in fume-hood

- Regulation of flowrates, pressures and temperature in both feed and extractant circuit

- Single-channel ceramic membranes, flat-sheet polymeric membranes and commercial hollow fiber modules

- Standard volume feed and extractant tank: 0,5L (replaceable by 1L and 2L tanks)

- Typical working T: 20 – 40°C