Circular & biobased economy

In a circular and bio-based economy, we make sure that products and materials are used and re-used for a longer time. We see waste as a valuable raw material. We limit the use of fossil raw materials as much as possible. They are finite, make us very dependent as a continent and place a heavy burden on our climate. When we do need new raw materials, we use alternative biological raw materials and CO2. VITO helps companies, governments and citizens pave the way towards a circular future.

What is a circular economy?

A circular economy is about more than just recycling. It is an economic system in which we maintain the complexity and functionality of a product for as long as possible, instead of breaking a product down to its base materials, incinerating it or dumping it as waste, once it has been used.

A circular economy is based on closed material loops. This means that as little material as possible leaves the loop through incineration or landfill. Only a minimal amount of new raw materials needs to be added.

The circular economy requires a system change: a change in the behaviour of producers and consumers. Committing to a circular economy reduces the burden on the environment and the climate. It offers opportunities for businesses and reduces the EU's economic dependence on raw materials from abroad.

Why is a circular economy important?

- Raw materials are becoming scarcer and our natural resources are being depleted.

- Demand is increasing for raw materials that are not available in our region, making us dependent on other countries.

- It offers new opportunities to businesses.

- It helps to improve Europe's competitive position in the world.

- It has a positive impact on climate and environment.

How do we achieve the circular economy?

The transition to a circular economy requires a system change in which governments, manufacturers, consumers, and financial institutions each play an important role. In addition, technologies help us to achieve the circular objectives.

Technologies

The following digital technologies can be used to boost the circular economy:

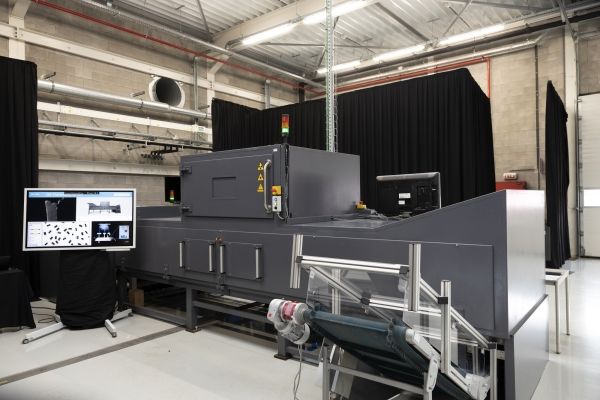

- Sensors and technologies to improve and automate the collection and sorting of waste and material streams.

- Virtual production processes that allow us to deliver a first real-world product straight away that meets the requirements, without a material-consuming pre-production phase.

- Technologies such as 3D printing that facilitate circular design and modular construction, which is necessary for easy disassembly and repair.

- Digital applications that allow us to share products, such as sharing platforms.

- Blockchain technology that allows us to share information about the life-cycle and value chain of products.

Products and services for a circular economy

Circularity in different sectors

Alternative resources: biomass

Wind and solar energy are known as alternatives to fossil raw materials. But there are other possibilities, such as biomass. These are natural materials derived from wood, algae and insects, for example.

We do not only research the application possibilities of these alternative raw materials. We are also researching installations that can convert the processed raw material and the entire value chain. We look beyond the theory. Because what works on paper and in a lab must also be tested for its practical and economic feasibility.

Circular water

In recent years, the water supply in Flanders has come under heavy pressure, due to a combination of rising consumption and increased paving. In addition, climate change means that we are increasingly having to deal with both flooding and drought. In order to evolve towards a more robust water system, it is important to focus on circular water management: using water in the same cycle for as long and as high a quality as possible, reducing the demand for water.

VITO helps companies to translate circular principles into concrete opportunities in their business operations. This can be done, for example, by reusing waste water and sharing water with other companies through smart networks. For example, we are part of B-watersmart. These are living labs spread throughout Europe where the reuse of (waste) water is tested. VEG-i-TEC focuses on water research tailored to the potato, fruit and vegetable sector. Companies can call on the research centre to make their processes more sustainable and circular.

Apps and games about the circular economy

Learn all about the circular economy through interactive games for all ages and target groups, from primary education to corporate settings. Use these interactive learning tools anywhere!

ResourCity

The latest augmented reality game app that allows you to learn about chemistry and technology while out and about. It is also a novel way of discovering what materials can be found in your city or municipality.

EcoCEO

EcoCEO brings concepts and strategies for the circular economy to your classroom and introduces your pupils to sustainable entrepreneurship and developments in the resource sector. Play, learn, and have fun!

Risk&RACE

Risk & RACE gives you an insight into the opportunities and challenges of the circular economy in a fun way. It consists of a board game designed to spark an entrepreneurial spirit and introduce players to decision making and business models in the circular economy.

Free online course circular economy

Do you want to dive deeper into sustainable business and the circular economy? Then follow our free online course Circular Economy - Sustainable Materials Management at your own pace.

Experienced researchers and practitioners from across Europe will guide you through the key elements and challenges in the transition to a circular economy over the course of 5 modules.