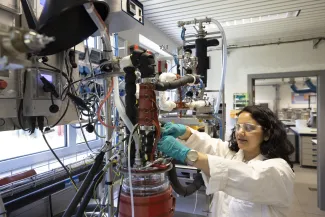

VITO offers expertise and equipment for bioprocess conceptualisation, development and intensification, techno-economic assessment and support for upscaling. It has an extensive track record in continuous fermentations (>1000 hours of operation), in running single- and 2-stage set-ups with or without integrated membrane filtration, using 1st and 2nd generation feedstock or gaseous substrates. Fermentations can be run with wild type microorganisms, GMOs (Biosafety Level 2) and mixed cultures.

Our equipment

| Size | # | Type | Material | Special features |

| 2-5 L | 4 | CSTR* | Glass | Can be coupled with pervaporation and other separation units |

| 5 L | 1 | CSTR | Glass | Coupled with membrane filtration unit for high cell density fermentations |

| 7 L | 1 | CSTR | Glass | Equipped with online methanol sensor |

| 7 L | 1 | CSTR | Stainless steel | Equipped with online methanol sensor // Pressurizable up to 2 bar |

| 15 L | 1 | CSTR | Stainless steel | ATEX // food grade // pressurizable up to 10 bar // coupled membrane filtration // supply of CO2, H2, CO, O2, N2, gas mixtures such as syngas or real offgases // online gas chromatograph for headspace analysis and control |

*Continuous Stirred Tank Reactor

For whom is this lab interesting?

- Building managers

- Operators of charging stations

- Developers of energy m

What can you use this lab for?

- In this lab, smart charging strategies can be scaled up from simulation to practical testing. Thus, charging strategies can be improved to minimize energy costs, CO2 emissions or grid load.

- Research on flexibility services for:

- Local utilization in the building

- Avoid peak off-take from grid

- Increase self-consumption of solar panels

- Responding to variable energy prices

- The energy community, e.g. a business park or residential area: how to ideally deploy charging behavior and battery potential to ensure energy supply to users and minimize grid load.