Mobilising grass optimally towards our circular economy

Every year, an estimated 427 000 tonnes of grass is cut in Flemish roadsides and nature reserves. Today, this grass is mostly composted; in addition, part of it remains at the place where it is cut. However, it could also be used as a building block for various products such as insulation material, fertiliser, biogas or paper. Transport and logistics are an important part of the cost here - of around €45-70/tonne. VITO researchers were commissioned by the Circular Economy Policy Research Center to find out how this grass can be optimally mobilised into our circular economy in various scenarios.

Grass: from roadside to product

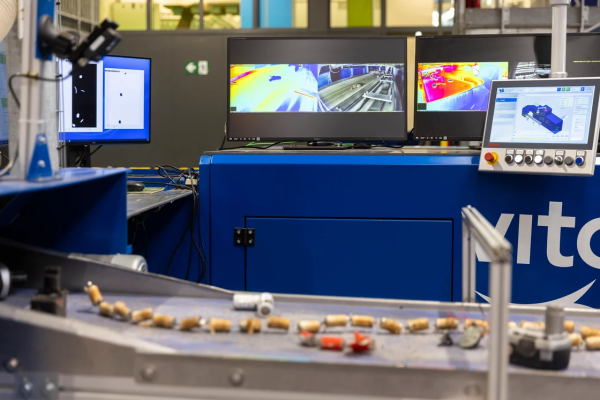

To select the best mobilisation strategy for grass use, the MooV optimisation model was used. MooV investigates how grass can be maximally mobilised at the lowest possible logistic cost. Based on road typology, a map was drawn up for all of Flanders with an estimate of road verge locations. The grass map shows the location of about 15 000 ha of natural grassland and 15 000 ha of grass road verges. From each location, the logistics cost was taken into account, from mowing through storage to final processing. The risk of litter or contamination of the grass was also considered. Grass from nature reserves (165 000 tonnes per year) has a lower risk of contamination with, among others, litter and is therefore easier to use for higher-quality biomaterials such as insulation materials or composite materials based on grass fibres. Grass from municipal and highways (262 000 tonnes per year) is often of lower quality, making clean-up necessary.

Grass instead of fossil materials

The contribution of grass to the circular economy depends on which product can eventually be produced and which original product will replace it. For example, the production of biomaterials can replace the production of fossil materials. Grass-based compost can also be used instead of traditional fertilisers. Currently, of the potential 427 000 tonnes of grass, only 177 000 tonnes of grass is estimated to be used. So there are 250 000 tonnes of grass that can be additionally valorised. So there is enough grass present in Flanders to both produce new biomaterials and maintain current applications such as composting.

Minister for Innovation Jo Brouns: 'In Flanders we are committed to the bio-based bio-economy, to make new high-quality products from biomass such as biodegradable plastics or other biomaterials so that we become less dependent on fossil fuels. The study now nicely demonstrates that the large amount of cut grass can be a potential for Flanders' plans related to bioeconomy.'

'In a circular economy, waste does not exist. In it, all our waste becomes a building block for new products. This study shows that even with grass, which we have an almost endless supply of, we can make products. This makes us less dependent on fossil fuels and materials we have to import from abroad. A win for our wallet and for the climate,' says Flemish Minister for the Environment Zuhal Demir.

About the CE Center

Circular Economy Policy Research Center brings together researchers from KU Leuven, UAntwerpen, UGent and VITO and conducts policy-supporting research funded by OVAM and EWI. The main objectives of the support centre are to measure and map the transition to a circular economy and to analyse policy instruments and strategies that contribute to the transition as well as the impact of new trends on it. Research publications and results can be found at ce-center.be.

Channel Z broadcast a news report on the study including an interview with Ruben Guisson. Watch it below.