A road map for the decarbonisation of energy-intensive industry

How can industries in the European Union, such as the steel and chemicals sector, cement factories and oil refineries, reduce their CO2 emissions to net zero in the coming years and decades? Will they be able to make a substantial contribution to the intermediate European climate goals in 2030 (55 per cent less greenhouse gases) and the final horizon of climate neutrality in 2050? And how can they do this? These kinds of questions will soon be answered thanks to the AIDRES project (Advancing industrial decarbonisation by assessing the future use of renewable energies in industrial processes). Its rich experience with geographic energy studies was among the reasons why VITO/EnergyVille was given the lead for this initiative.

Energy-intensive companies in Europe must buy so-called emission rights for the greenhouse gases emitted. The rights are traded in the ETS system (Emissions Trading System). These companies, often known as ETS companies, are responsible for 45 per cent of the total emissions in the European Union. If the EU wants to achieve its climate objectives - intermediate targets in 2030 and the final goals in 2050 - then this requires a drastic reduction in the greenhouse emissions of ETS companies.

The ETS emission reduction can be accomplished in various ways. For example, by consuming less energy. By replacing fossil fuels with renewable sources, for example, with intense electrification or using green molecules, such as hydrogen. Or by capturing and storing the produced CO2 or – in the case of biogenic origin – making it available for reuse.

Industrial blueprints

Of course, a business’s chosen route to carbon neutrality depends on its individual nature. However, based on these characteristics, and which decarbonisation routes are possible, plus many external factors (mostly economic), this route can be predicted to a certain extent, or rather: modelled. And, that is of course interesting for the European policymakers, who are keen to keep their finger on the pulse as much as possible in the evolution towards a climate-neutral Europe in 2050.

Much research has already been done into the decarbonisation of energy-intensive industries. However, this often went into little depth, which meant it only reached sector level, without zooming in on individual clusters or clusters of production units. That’s not the case in the AIDRES project, led by VITO/EnergyVille and launched in January 2021. ‘We are working bottom-up, starting with detailed industrial blueprints on which we then apply our energy models,’ says Joris Valee from VITO/EnergyVille. ‘This means we include the impact of differences in production processes in our calculations and predictions, not only for existing processes but also for potential future ones, that may be launched as part of decarbonisation.’ The modelling is also based on a number of assumptions, such as future gas and oil prices, or the price of emission rights.

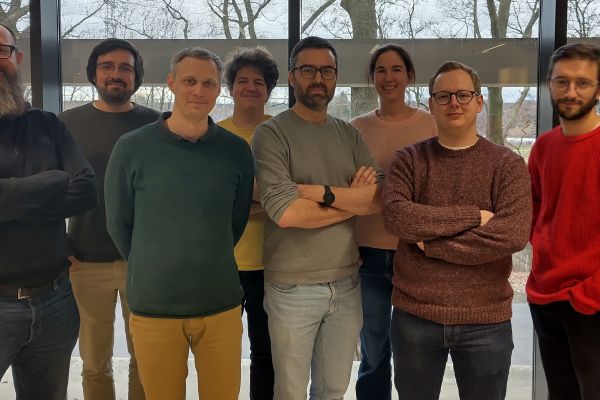

The AIDRES models end up providing data that reflect the anticipated evolution for a specific production process, for example, cement, over the coming years and decades. This is done with all kinds of indicators relating to a particular amount of end product (for example, one ton). An important indicator is the energy demand, but the cost is also presented, and subdivided into, for example, investment costs, operational costs and energy costs. The project is focused on six industries: steel, chemicals, refining, artificial fertilizer, glass and cement. Other partners in the AIDRES project, together with the project leader VITO/EnergyVille, are KU Leuven, Ghent University, VUB, EPFL and Dechema.

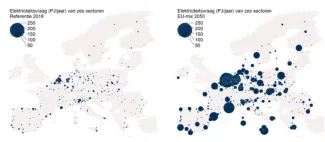

The project includes a spatial visualisation exercise, in addition to modelling. Indeed, the end results are linked to the business location and production units of the industries involved. This creates a clear and manageable visual geographical summary that will become accessible for consultation on an online database soon, probably by the summer of 2023, once the project is concluded. The visualisation is done on the platform of the Energy and Industry Geography Lab, a tool from the Joint Research Centre allowing datasets related to energy, industry and infrastructure to be visualised. The resolution of AIDRES visualisation will be up to so-called NUTS3, a level of European geographic division comparable with the size of a Flemish district.

Defining own climate objectives

The database supporting AIDRES modellers, contains data from different sources. The consultation and combination of all these sources is an important part of the project. ‘For some sectors, such as the steel industry and refineries, there are databases with detailed information about companies and about decarbonisation options,’ says Wim Clymans from VITO. ‘For other sectors, we actively need to search for data, for example, in annual reports, in environmental permits or in emission reports of greenhouse gases.’ However, companies and sector federations have also been consulted directly. Valee: ‘We have organised a number of workshops for industry delegates. This helps our progress, but it will also soon help theirs. After all, the project results can be beneficial in their decarbonisation plans. They can help to define a road map towards 2030, and then towards 2050. Then companies can also set their own objectives, based on realistic and solid scientific foundations.’

The collaboration with the industries concerned also helped in rapidly translating information into data that is useful and can be modelled. After all, the implementation of AIDRES, upon the request of the Directorate-general for Energy from the European Commission, is a kind of service, Valee: ‘This means that you must quickly produce results, and ones that are also suitable for the market.’ Another advantage of the rounds of consultation with industries is actually that the results of the project will soon be broadly supported.

In addition to companies from the six industries concerned, electricity manufacturers and network managers will also be interested in the results from AIDRES. Clymans: ‘The decarbonisation of energy-intensive industries will have an enormous impact on the electricity grid. The project will generate valuable information for (future) owners of wind farms or solar parks, for example, about where and when more capacity will be necessary. Grid operators can then promptly establish where and when they need to strengthen transmission lines, for example.’ In fact, KU Leuven (one of the partners at EnergyVille) is responsible for modelling the impact on the European electricity net.