AirPED: Advancing air safety

AirPED is a comprehensive research project on fire risks of portable electronic devices in checked luggage and enhancing aircraft fire suppression systems standards, including halon replacement.

The number of lithium battery-related fire incidents on and around aircraft has been steadily rising, with an average of three overheating incidents recorded globally every two weeks, compared to just under one per week in 2018. The aviation industry has long recognised the safety risks associated with the growing use of lithium batteries, leading to regular updates in regulations. These incidents remain a serious concern due to the risk of thermal runaway, which can result in fires, smoke, and even explosions.

Many of these incidents occur in the cabin and are triggered by portable electronic devices (PEDs) carried by travellers. While these events pose a certain risk to the aircraft, this risk is manageable with the measures available in today's cabins. But are the current safety systems able to handle the growing fire risks posed by an increasing number of PEDs in checked baggage and more checked baggage containing PEDs?

Need to redefine fire suppression criteria

The main fire suppressant agent used in current aircrafts is Halon 1301. It has been reported that Halon-based products can extinguish efficiently a lithium battery. However, with the planned phase-out of halon due to environmental concerns, there is a need to redefine fire suppression criteria. In the context of Halon replacements, Minimum Performance Standard (MPS) sets the minimum required effectiveness for alternative agents to ensure they meet or exceed Halon's performance.

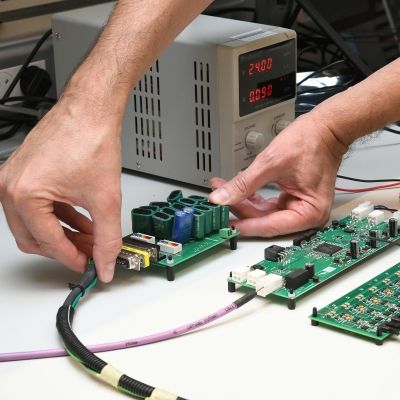

This requires complementing the existing MPS with additional testing that specifically addresses fire scenarios involving lithium batteries. Such tests should evaluate the effectiveness of alternative suppression agents, containment strategies, and system response times to ensure that future fire protection standards remain effective against evolving threats.

Testing portable electronic devices in luggage

The primary objective of the AirPED project is to conduct tests on Portable Electronic Devices (PEDs) placed in passengers' checked baggage to accurately assess fire risks, including ignition, growth, and propagation, within a cargo compartment representative of modern large transport aircraft (Class C). And through a comprehensive experimental evaluation, the project aims to assess the current version of the Minimum Performance Standard (MPS) tests, incorporating additional considerations and potential enhancements to improve their effectiveness.

Consortium and funding

The AirPED project is a research initiative led by the European Union Aviation Safety Agency (EASA). This project has received funding from the European Union's Horizon 2020

research and innovation programme under grant agreement No MOVE/B3/SUB/2020-243/SI2.826742.

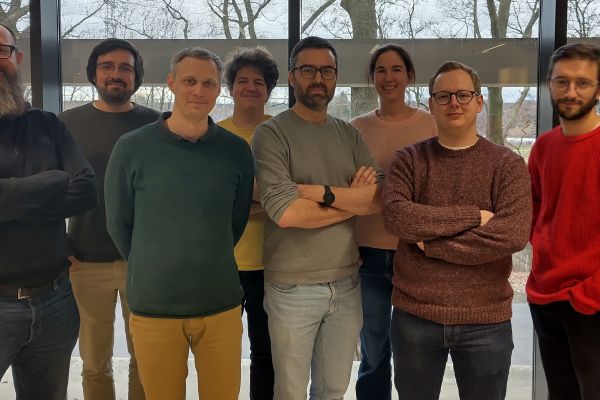

VITO is leading the consortium formed with Airbus and DLR.

Project partners and roles

VITO/EnergyVille

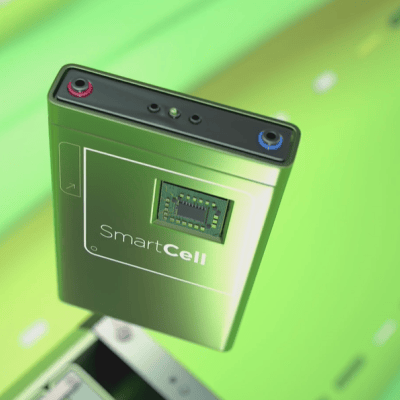

VITO plays a leading role in the AirPED project, serving as the coordinating partner. As a renowned European research center, VITO's battery testing and safety research experience, including past leadership in projects like Sabatair, strengthens its capability to analyse lithium battery failures and recommend safety measures for air transport.

Airbus Operations GmbH

Airbus plays a crucial role in the AirPED project by contributing its extensive expertise in aircraft fire protection systems, fire suppression technologies, and cargo safety regulations. As a key consortium partner, Airbus provides technical knowledge and practical experience in designing, certifying, and improving both active and passive fire protection measures for aircraft cargo compartments.

The Airbus Cargo and Fire Safety Department brings over 50 years of experience in developing and optimising fire suppression systems for different aircraft applications. Their involvement ensures that the project aligns with real-world aviation safety standards and regulatory requirements.

DLR (Deutsches Zentrum für Luft- und Raumfahrt)

The German Aerospace Center serves as a subcontractor in the AirPED project, bringing its expertise in fire testing, certification, and aeronautical safety research. DLR's primary role is to conduct full-scale fire experiments at its fire testing facility in Trauen, Germany, which includes a 1:1 aircraft cargo compartment mock-up designed to comply with Minimum Performance Standards (MPS). With its longstanding expertise in aircraft fire safety and MPS testing, DLR enhances the project’s ability to generate scientifically validated data on lithium battery fire risks and mitigation strategies.

Would you like to know more?

Feel free to contact Khiem Trad for more information about AirPED and related projects.