CHARAMBA: Artificial intelligence for material characterisation & real-time mass balances

Today, many recycling companies struggle with the value assessment of complex material/waste streams. The main issues are the costly and labour-intensive sampling procedures and subsequent chemical analysis, leading to long waiting times (often several weeks) and the associated financial uncertainty. To counter this, VITO initiated the development of an in-line characterisation technology.

With this technology, heterogenous and complex material streams can be assessed completely – eliminating the need for subsampling – and mass-balances can be produced ‘on-the-fly’. In fact, for each material particle a ‘digital twin’ is created which can be further assessed in a virtual way.

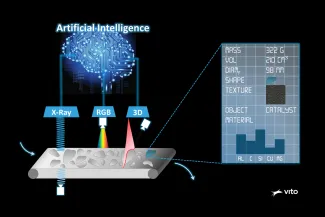

In this technology, the heterogenous waste particles are dispersed on a conveyor belt as a mono-layer and scanned using X-rays, a 3D laser scanner and a colour camera. Using artificial intelligence, the device recognises the individual particles and assigns several important physical parameters: size, mass, shape, material, texture, etc.

The technology behind CHARAMBA

Currently the technology is demonstrated successfully for a handful of streams on the level of relatively small samples, e.g. a few buckets (‘scan-the-bucket’). In the current CHARAMBA proposal, VITO wishes to further mature the technology, i.e. scale it up to an industrial relevant level or, in other words, to ‘scan-the-truck’.

The project focused on two required innovations:

- a framework to efficiently tailor hardware, software and models to new streams and customer challenges and

- a performance scale-up of the technology, to deal with industrially relevant throughput and provide stream statistics in real-time.

Project partners

More info

Would you like to know more about the Characterise-to-Sort technology? Feel free to contact Kris today.