LigniOx: converting lignin into sustainable dispersants

With this project, we wanted to demonstrate that the unique alkali-O2 oxidation technology adds value on a technological and economic level. Thanks to this technology, underutilised and lignin-rich side streams can be turned into cost-efficient and biobased dispersants, such as high-performance concrete plasticisers.

A huge advantage for biorefineries

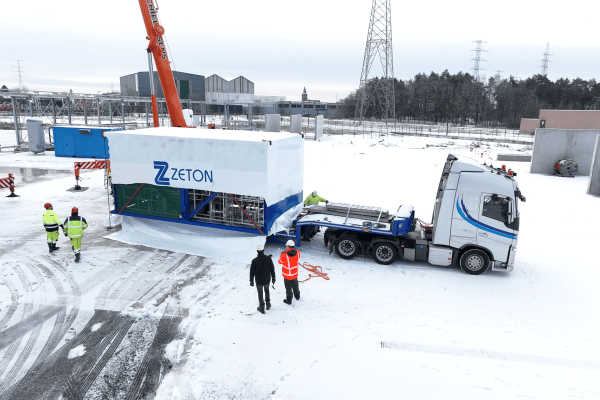

With a mobile pilot, we demonstrated the processes in biorefineries. We introduced the oxidation process and the performance of the final products under business circumstances.

By introducing the technology that way, we wanted to pave the way for new industrial process installations and new lignin-based products. These new products will offer a sustainable alternative to the synthetic plasticisers and lignosulphonates used now.

The main advantage of this innovative technology is that it can be integrated into existing lignocellulosic biorefineries effortlessly. Additionally, the chemical industry may exploit this technology as an independent entity.

When lignocellulosic biorefineries valorise their side streams in this way, they will be able to be more cost-efficient and handle their resources more efficiently. At the same time, they produce sustainable resources for the chemical industry at a low cost.

Our goals

During this project, we had several goals:

- Determining the most common techno-economic concepts for industrial process installations.

- Optimising the circumstances of oxidation for variable lignin resources.

- Developing processing techniques based on membrane technology so the final products meet the quality demands.

Funding

This project was backed by the European Union’s research innovation programme Horizon 2020, the Bio-based Industries Consortium and Bio-based Industries Joined Undertaking.