Research infrastructure for (gas) fermentation and enzymatic conversions

Want to transform your approach to production by moving towards sustainable, efficient and competitive processes through bioconversion – integrating biocatalysis and fermentation? At VITO, we combine world-class expertise with state-of-the-art research infrastructure, supporting you at every step, from process conceptualisation to upscaling of industrial biotechnology and biomanufacturing processes. We help you innovate, cut costs, and deliver on quality, efficiency, and sustainability in demanding markets.

VITO offers specialised infrastructure that supports two key aspects of biotechnological conversion: enzymatic conversion and (gas) fermentation. For enzymatic conversion, we provide bioreactors with in-situ product recovery and membrane bioreactors. For (gas) fermentation, we offer fermentors, a small-scale high-pressure fermentor and an ATEX-certified pilot high-pressure fermentor, ideal for conversions of CO₂, H₂, CO and syngas.

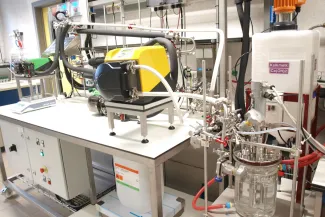

Enzymatic conversion infrastructure

Bioreactors with in-situ product recovery technology

- Up to 5 liter volume

- Coupled with pervaporation unit for in-situ product removal if needed

- ATEX and food grade

- Up to 60°C

Membrane bioreactors

- 1-15 liters reactor vessels

- Coupled with flexible membrane filtration unit for product tailoring or fractionation

- Mobile

- Inline viscosimeter

- Up to 50 bar

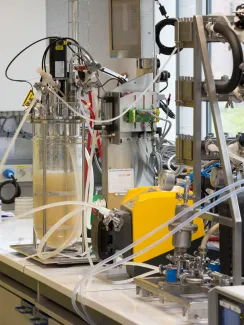

(Gas) Fermentation infrastructure

Fermentors

- 2-7 L

- Coupled with microfiltration, ultrafiltration, pervaporation and other separation units

- Suited for high cell density fermentation and in-situ product recovery

- Equipped with online sensor measurement and control

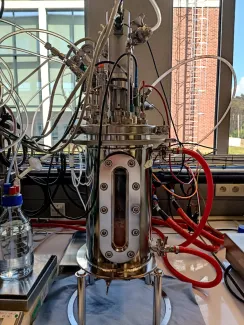

Small scale high pressure fermentor

- Up to 2 bar pressure

- Suited for high cell density fermentation

- Equipped with online methanol sensor

Pilot high pressure fermentor

- ATEX

- Food grade

- Pressurisable up to 10 bar

- Coupled with membrane filtration

- Suited for conversion of CO2, H2, CO, gas mixtures such as syngas or real offgases

- Equipped with online gas chromatograph for headspace analysis and control

What can you use it for?

- Developing and testing a biobased alternative for an existing (chemical) process

- Improving your current fermentation processes

- High cell density fermentations

- Selective (co-)product removal in your (bio)processes (in-situ product recovery)

- Valorising CO2 emissions

- Assessing gas fermentation or C1 fermentation processes

Why choose VITO?

- Proven industrial expertise and solutions in chemicals, biofuels, and food & feed projects – boosting competitiveness and sustainability

- Flexible state-of-the-art infrastructure: from lab to pilot scale, including tailored process configurations

- Reliable project support: from concept, development, and techno-economic modeling to upscaling and product sample delivery

- Full regulatory and biosafety compliance for challenging biological processes

Contact us for more information

Ready to innovate through enzymatic or microbial fermentation processes? Want to use our research infrastructure for (gas) fermentation and enzymatic conversions? Contact Marzio Monagheddu today to discuss the full potential of biocatalysis and fermentation for your business.