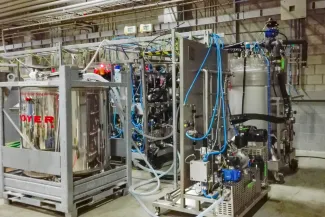

Mobile solvent filtration units

At VITO we offer a range of mobile solvent filtration equipement which uses organic solvent based pressure-driven membrane filtration. The units can be used for a wide range of applications such as concentration, purification and solvent swap of APIs or clean-up of viscous waste oils, plastic oils, lignin oils, etc.

What can you use them for?

- Concentration, purification and solvent swap of APIs

- Solvent recovery from crystallisation mother liquors

- Solvent recovery from edible oil miscella

- Pre-concentration and fractionation of natural products from solvent-based extracts

- Clean-up of viscous waste oils, plastic oils, lignin oils, etc.

- Purification of (alternative) fuels and other related hydrocarbon streams

The units

Mobile solvent filtration pilot unit 1

Technical features

- Unique mobile cross-flow pilot unit for solvent-based pressure-driven membrane filtration (OSUF, OSN, OSRO)

- ATEX/GMP design specifically meant for pharmaceutical and food applications (316 L, Kalrez)

- Max. 50°C (non-ATEX: 80°C) – 45 bar

- Multi-channel ceramic membranes and 4040-type spiral-wound elements

- Circulation flow rate up to 7 m³/h and permeate flow rate up to 500 l/h

- Feed tank of 400 L, min. working volume 70 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

Reference industrial showcases

- Recovery of API from distillation residue (The Netherlands)

- Purification and concentration of adjuvant for pre-commercial anti-diabetes drug (Switzerland)

- Purification and solvent transfer of API (UK)

- Purification of high purity solvents for semi-conductor applications (Belgium)

Mobile solvent filtration pilot unit 2

Technical features

- Unique mobile cross-flow pilot unit for solvent-based pressure-driven membrane filtration (OSUF, OSN, OSRO)

- ATEX/GMP design specifically meant for pharmaceutical and food applications (316 L, Kalrez)

- Max. 80°C – 45 bar

- Multi-channel ceramic membranes and 4040-type spiral-wound elements

- Circulation flow rate up to 7 m³/h and permeate flow rate up to 500 l/h

- Feed tank of 400 L, min. working volume 60 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Batch and continuous (feed-bleed) operation possible

Reference industrial showcases

- Recovery of acetone from edible oil miscella (The Netherlands)

- Removal of impurity from vitamin API (Switzerland)

- Recovery of valuable compound from wastewater stream (Switzerland)

- Work-up of solvent/water-based stream rich in Pd and KOH (Belgium)

Mobile solvent filtration pilot unit 3

Technical features

- Unique mobile cross-flow pilot unit for solvent-based pressure-driven membrane filtration (OSUF, OSN, OSRO)

- ATEX design specifically meant for (higher temperature) chemical applications (316 L, Kalrez)

- Max. 130°C – 45 bar (ATEX heater)

- Multi-channel ceramic membranes and 4040-type spiral-wound elements

- Circulation flow rate up to 10 m³/h and permeate flow rate up to 500 l/h

- Feed tank of 400 L, min. working volume 60 L

- Semi-automatic operation, fully instrumented with real time process monitoring and data acquisition

- Batch and continuous (feed-bleed) operation possible

Reference industrial showcases

- Fractionation of lignin oil (Germany)

- Purification and concentration of oxidized lignin (Belgium)

- Purification of hydrocarbons product stream (Belgium)

- Recovery of base oil from used lubricating oils (Belgium)

- Clean-up of source-contaminated hydrocarbons stream (Belgium)