High-performance electrodes for electrochemical processes

Gas diffusion electrodes (GDEs) are key building blocks in modern electrochemical and bio-electrochemical processes. They help convert gases such as CO₂ into valuable products, support cleaner wastewater treatment and enable more energy-efficient production methods.

At VITO, we design and optimise GDEs from lab scale to pilot scale, helping companies reduce costs, shorten development times and improve process performance. If you're exploring new electrochemical solutions, we are ready to discuss your challenge.

Proven innovation: European patent for next-generation GDEs

VITO’s leadership in electrode development is supported by strong intellectual property. Our most recently granted European patent EP4182491B1 covers a new generation of carbon-free, metal-based gas diffusion electrodes designed for long-lasting and efficient CO₂ electroreduction.

These electrodes address common limitations of carbon-based GDEs by offering:

-

greater stability under industrial operating conditions

-

lower degradation and flooding risks

-

better compatibility with CO₂ electrolyser systems

-

a more robust, scalable route towards commercial CO₂ conversion

Interested in patented electrode technology? Let’s talk about licensing or collaboration.

What industry challenges do our GDEs solve?

Companies come to VITO when they face challenges such as:

- high costs of platinum-based electrodes

- electrode degradation or limited lifetime

- difficulty scaling up from lab experiments to pilot or industrial scale

- low productivity due to mass-transfer limitations

- complex, multi-step processes

- inefficient downstream handling of gaseous products

- the need to simplify operations and reduce cost

If any of these issues sound familiar, our experts can assess your process and advise on the best path forward. VITO tackles these issues with reliable, scalable and cost-effective electrode solutions. Interested? Contact us to discuss your specific challenge.

The results you can expect

Our gas diffusion electrodes help industrial clients achieve:

- up to 10x lower electrode cost, thanks to low-cost carbon materials

- stable, long-term performance, proven over year-long tests

- a more sustainable process, with no solvents and less waste

- lower investment and operating costs for the complete process

- a shorter time-to-market through easy scale-up from small lab setups to pilot units

- improved process efficiency thanks to better mass transfer

- compatibility with industrial membranes such as Zirfon

Our goal is simple: make your electrochemical process more competitive. If you want measurable improvements in cost, efficiency or reliability, let’s explore what we can achieve together.

Why industry partners choose VITO

Strong expertise, a multidisciplinary team and a global network

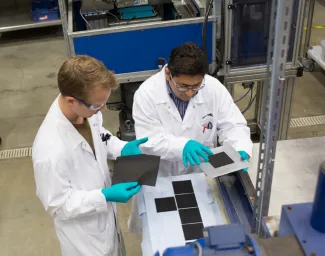

Our experts combine electrochemistry, materials science, catalysis and separation expertise. We develop electrodes in many shapes and sizes, from small 10 cm² samples to large 1 m² plates. Our extended international network of universities, industrial partners and research institutions ensures continuous knowledge exchange and access to the latest breakthroughs.

Looking for a partner with proven expertise? Contact us to explore what’s possible.

Advanced infrastructure from lab scale to pilot scale

We offer feasibility studies and process advice. We help design conversion plants and develop electrodes using commercial or customer-provided materials. Our facilities cover every step from centimetre-scale experiments to fully operational pilot units (GMP and ATEX certified). This allows companies to test, refine and scale their processes in a safe, realistic environment before making major investments.

If you need a test environment or pilot-scale support, our infrastructure is at your disposal.

Tailor-made solutions and ready-to-license technologies

Every industrial challenge is unique. We design electrodes around your specific needs, whether it’s for a lab test or a large pilot installation.

We also offer ready-to-use patented technologies:

- VITO CORE®: multilayer electrodes made by cold rolling

- VITO CASE®: multilayer electrodes made by casting

- large segmented electrode arrays up to 0.85 m²

These provide fast, de-risked routes to industrial implementation. If you’re looking for custom development or licensing opportunities, our team is ready to support you.

Examples of what we deliver

Low-cost air cathodes for microbial fuel cells (MFCs)

Replacing platinum with our carbon-based electrodes (VITO CORE® and VITO CASE®) resulted in:

- 10x lower cost

- strong performance in both artificial and real wastewater

- only 30% performance loss after one year

- successful scale-up from small samples to m²-scale

Do you want similar cost savings or long-term stability? Let’s explore your application.

Custom tubular electrode for a designer MFC lamp

A Dutch designer needed a unique tubular electrode for a microbial fuel cell lamp. Using our flexible VITO CORE® technology, we created a leak-proof electrode that worked perfectly. The lamp won a design award at Dutch Design Week in 2016.

If you need unique shapes or custom engineering, our team can make it happen.

Large segmented electrode array for pilot use

A customer needed a large electrode for a pilot system working with wastewater. VITO developed a robust 0.85 m² electrode that:

- could withstand the pressure of 100 litres of water

- provided stable, even current distribution

- connected several smaller electrodes efficiently

Looking to scale up to pilot or pre-industrial size? We can help design and build your solution.

Let’s advance your electrochemical process together

If your company wants to lower costs, boost efficiency or scale up electrochemical or CO₂-conversion technologies, VITO can help. Contact us to discuss your challenge, explore collaboration options or start a custom development project. We are ready to support your journey from idea to implementation.

Contributions to major European innovation projects

VITO plays a leading role in several European innovation programmes.

VIVALDI (H2020): Circular CO₂ conversion for industry

VIVALDI develops carbon-free, metal-based electrodes and processes to convert industrial CO₂ emissions into valuable chemicals. VITO contributes by creating durable GDEs for efficient CO₂ electroreduction, protected by our European patent EP4182491B1.

TRAMPOLINE (MSCA): Advancing microbial electrochemical technologies

TRAMPOLINE advances next-generation electrodes for microbial electrochemical technologies. VITO developed improved GDE materials that boost performance and stability in bio-electrochemical systems.

CLUE: Selective CO₂ electroreduction with metal clusters

CLUE focuses on using metal clusters as innovative catalysts for selective CO₂ electroreduction. VITO develops electrode structures that integrate these clusters to enhance efficiency and product selectivity.

FUELS-C: Biofuels from CO₂ and organic waste

FUELS-C develops new ways to turn CO₂ and organic waste into biofuels. VITO contributes by creating advanced electrodes that convert CO₂ into formic acid, which can be used to produce electricity in fuel cells.

Get-A-Met: Recovering critical metals from industrial streams

Get-A-Met develops new technologies to recover critical metals from low-concentration industrial streams. VITO supports innovations that address raw-material scarcity and improve circular use of valuable resources.

E2C: Electrons to high-value chemicals

E2C accelerates the development of Power-to-X technologies by converting renewable electricity and CO₂ into valuable chemicals. VITO contributed by developing an electrode platform for efficient CO₂ electroreduction.

Representative papers

- Singh, C., Song, J., Prasannachandran, R., Rodriguez, A.G., Shen, J., Chen, Z., Vaes, J., Birdja, Y.Y. and Pant, D., 2026. Unlocking long-term stability in metal-based gas diffusion electrodes for CO₂ electroreduction. EES Catalysis. DOI: https://doi.org/10.1039/D5EY00330J

- Santoro, C., Bollella, P., Erable, B., Atanassov, P. and Pant, D., 2022. Oxygen reduction reaction electrocatalysis in neutral media for bioelectrochemical systems. Nature Catalysis, 5(6), pp.473-484.

- Rossi, R., Jones, D., Myung, J., Zikmund, E., Yang, W., Gallego, Y.A., Pant, D., Evans, P.J., Page, M.A., Cropek, D.M. and Logan, B.E., 2019. Evaluating a multi-panel air cathode through electrochemical and biotic tests. Water research, 148, pp.51-59.

- Bajracharya, S., Vanbroekhoven, K., Buisman, C.J., Pant, D. and Strik, D.P., 2016. Application of gas diffusion biocathode in microbial electrosynthesis from carbon dioxide. Environmental Science and Pollution Research, 23, pp.22292-22308.

- Alvarez-Gallego, Y., Dominguez-Benetton, X., Pant, D., Diels, L., Vanbroekhoven, K., Genné, I. and Vermeiren, P., 2012. Development of gas diffusion electrodes for cogeneration of chemicals and electricity. Electrochimica Acta, 82, pp.415-426.

Questions about gas diffusion electrodes

Yes, both the VITOCoRe and VITOCaSE electrodes are protected with a trademark/patent.

Yes, we offer diffused samples with 10 and 400 cm² for application testing.