Lignin, source of bio-aromatic compound

Lignin is one of the most common organic materials and the most abundant natural source of aromatic compounds. For example, it is mass produced as a by-product of the manufacture of wood pulp and paper. It can replace many aromatics of fossil origin in the chemical industry.

Aromatic components in daily life

Aromatics are building blocks for everyday materials, from plastics to textiles. They make up 40% of all chemical building blocks, providing functionality like stiffness, scratch resistance, and stability. By using bioaromatics from lignin we can increase the bio-based content and avoid toxic components. Aromatics are everywhere. Some of the common uses in your home include insulation, adhesives, floors, MDF boards, coatings, sealants.

Properties of lignin

Different lignins add different properties to materials.

- Stability

- Rigidity

- Improved scratch resistance

- Anti-bacterial and anti-microbial properties

- Waterproofing

- Increased UV blocking

- Anti-oxidative properties

- Adhesion

- Thermal resistance

Towards lignin-based applications

We have been focused on the production of bio-based synthetic resins of two types: epoxy resin and phenolic resin. This will increase the sustainability of these materials, and it will make the resins part of a broader circular value chain as lignin comes from secondary and waste flows. It is also our ambition to introduce recyclability in these products.

Epoxy resin

Epoxy resin contains bisphenol A, a chemical that has built up a negative reputation due to its toxic effects on the environment and human health. VITO has developed a patented method to make epoxy resin completely bio-based from lignin and saturated fatty acids, so that lignin can phase out bisphenol A over time.

Polyurethanes

Polyurethanes are very versatile class of materials, used in different applications including insulation materials, coatings, and flooring. By introducing biobased content and replacing the polyol with lignin derived building blocks, it is possible to reduce the CO2 footprint. Moreover, combining biobased and recyclable content is a new area of development that could generate additional benefits.

Phenolic resin

Phenolic resin is found in a wide variety of applications, including insulation foam, building materials, car parts, and adhesives. It’s our goal to partially replace phenol, a basic chemical substance of fossil origin, in phenolic resin by lignin. That’s why we are collaborating with partners such as INEOS, SBHPP and KINGSPAN and other knowledge institutions UGhent and INCAT research group within the framework of the BIORESAL project (Catalisti) to make this happen.

The use of these biobased phenolic resins will be tested and evaluated in industrial foam insulation applications and in the production of moulding compounds. With BIORESAL we are currently aiming to scale up to a one-tonne production trial of lignin-based phenolic resin.

Acrylic resin

A third type of resin that VITO is researching - on a smaller scale - is synthetic resin based on acrylic fibres. Acrylic resin is a common ingredient in latex paint. It is considered extremely weatherproof, making it ideal for outdoor applications. We are currently looking for possible applications, and for partners to cooperate with.

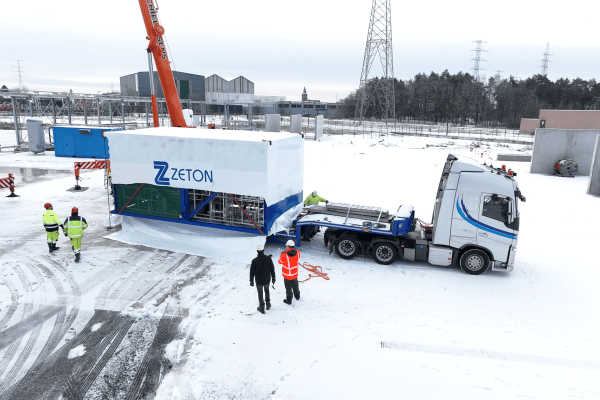

Upscaling production

VITO is looking to collaborate with an industrial partner to upscale the production process of lignin oil to multi kton per year via a proof of concept of the technology using the pilot infrastructure, i.e. LignoValue (ERDF project) and Pillar (LSI Moonshot-Catalisti project).

Want to know more about lignin and our pilot infrastructure?

Are you looking to replace your fossil-based aromatics with lignin-based aromatics and develop more sustainable products? Feel free to reach out to Kelly.