LignoValue Pilot inaugurated

Europe's first and only pilot line of bioaromatics from lignin

Mol, 6 October 2022: today the first and only pilot line of bio-aromatics from lignin in Europe was officially opened at the VITO site. Replacing fossil-based products with bio-based, high-performance and safe alternatives represents a major economic challenge for the European chemical industry. Several studies have identified biomass containing lignin (e.g. wood, grass, straw, corn straw) as the biomass of choice for the sustainable production of chemicals and especially so-called bio-aromatics. The next step was to design and develop a pilot plant to produce bio-aromatics on a scale relevant to industry.

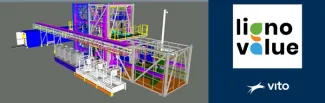

With the European Regional Development Fund (ERDF) project LignoValue Pilot, Biorizon co-initiator VITO, Worley Belgium and PMV realised a pilot line to demonstrate technologies to depolymerise lignin in a continuous process. The pilot plant allows proof-of-concepts of the different process steps to be delivered. The LignoValue Pilot is moreover located on a specialised site, where safety, material supply and product flow are guaranteed. The proximity of VITO, Flanders' sustainability research organisation, is a major asset.

Lignin, raw material with unknown potential

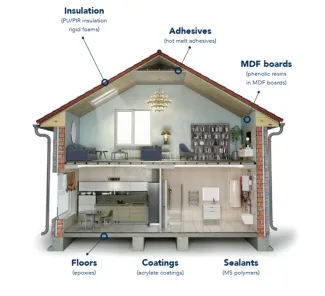

Lignin is one of the most abundant organic materials on earth. It is a molecule that nature itself produces in the cell wall of plant cells, giving strength and firmness to plants and trees. The fact that plants, shrubs and trees stand upright is due to the lignin it contains. Thanks to its chemical structure, lignin can replace many substances with aromatic compounds in the chemical industry, which are currently of fossil origin. 40% of all chemicals are currently fossil-based aromatics, including phenol and bisphenol A, respectively toxic and harmful to humans and animals. Phenol and bisphenol A are present among others in synthetic resins, which have a wide range of applications in various sectors ranging from construction over mobility and transport to the plastics industry.

Lignin is mass-produced as a by-product of, for example, the current pulp and paper industry. Most of that lignin is currently incinerated and thus only valorised energetically. As a feedstock for bio-aromatics, lignin has much more potential.

Lignin-derived bio-aromatics will lead to innovative development paths in the chemical industry due to an extensive arsenal of new functionalities and thus material applications and their reduced toxicity compared to fossil-based building blocks. Moreover, the use of lignin and its derived bioaromatics adds several properties to materials, such as stability, stiffness, improved scratch resistance, anti-bacterial and anti-microbial properties, waterproofness, increased UV protection, anti-oxidative properties, adhesion, thermal resistance, ...; properties that lignin naturally possesses thanks to its unique chemical structure.

For years, VITO has been at the forefront of research into the use of lignin as a basic resource for chemicals. Hence VITO, together with TNO (Netherlands) is founder of the Shared Research Centre Biorizon and responsible for the research line developing bio-aromatics from lignin. Biorizon aims to enable the commercial production of bio-aromatics from both sugars and lignin to contribute to a sustainable and profitable 'green' chemical industry.

Bridging the gap between development and implementation

Most of the processes for producing lignin-based bioaromatics have already been developed and demonstrated at lab scale. Since 2018, VITO has committed to design and build a pilot plant, i.e. LignoValue Pilot, that will enable the first production of bioaromatics from lignin. Here, Worley Belgium is the engineering partner, also investing in their own knowledge acquisition through the ERDF LignoValue Pilot project. The LignoValue Pilot was built by Dutch engineering company Zeton and installed at the VITO site in early 2022.

To achieve an industrially relevant breakthrough in this field, the pilot plant can produce more than 100 kg of innovative bio-aromatics on a daily basis, and through continuous processing. To this end, lignin will be cut into smaller chemical building blocks in a solvent in the presence of a catalyst and hydrogen. The availability in sufficient quantities of these small lignin-based building blocks will create a new value chain of innovative bio-aromatics, in cooperation with material producers such as INEOS, Kingspan and SBHPP. The new value chains will contribute to reducing the chemical industry's dependence on fossil and secondary raw materials, contributing to reducing the effects of climate change (CO2 reduction).

Moreover, the intended pilot line is flexibly designed so that different process conditions can be adapted and tested to produce the desired bio-aromatic fractions for market-oriented applications and product developments. All this should allow to provide the necessary techno-economic proof-of-concepts to reach the ultimate goal: building and operating a demo plant in Flanders for the conversion of lignin to bio-based functionalised aromatics and the development of a lignin-based value chain of new chemicals.

Jo Brouns, Flemish Minister for Economy, Innovation, Work, Social Economy and Agriculture, says: "For the sustainable transition to a climate-neutral society, the bio-economy is of enormous importance. If we can turn biomass and lignin into circular resources and products, we will thus become less dependent on fossil fuels. With Flanders, we are a pioneer in the bio-economy, and with the opening of the LignoValue Pilot Plant, we are strengthening our position in it. After all, this pilot infrastructure is a crucial intermediate step to develop lab-scale experiments towards larger-scale industrial processes."

Interested companies can join the Shared Research Centre Biorizon community for free at www.biorizon.eu/community/join/ and register for Biorizon's 9th annual virtual event on Thursday 1 December, including a keynote from Decathlon at 9th-biorizon-bio-aromatics-event.b2match.io/.

More info about VITO's research group SPOT (Sustainable POlymer Technologies)