Circular textile processing in Flanders: new report lays the foundation for a sustainable textile recycling value chain

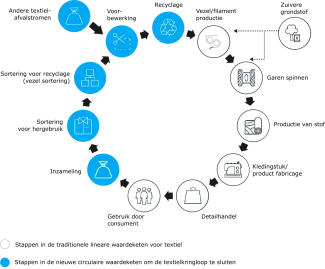

Textile processing in Flanders is undergoing a major transition. Collection for reuse alone is no longer sufficient: sorting, pre-processing and recycling of non-reusable clothing are becoming essential. The Living Lab 'Labs on Fibre' investigated how these residual textile streams can be locally prepared for recycling. Within this project, VITO demonstrates how collaboration, economies of scale, technological choices, and strategic location selection can pave the way towards an efficient, circular textile value chain for Flanders.

At the heart of the report ‘Het textiel-onderstroom model’ is the MooV model, scientifically developed by VITO for the strategic optimisation of logistics chains. For Labs on Fibre (LoF), the core MooV model was adapted to the textile sector’s specific characteristics, transforming it into the LoF model. This model was then used to systematically compare different scenarios and network configurations in the textile value chain, focusing on mobilisation costs, capacity utilisation and workforce deployment.

Key findings

-

Centralisation pays off: By centralising textile residual streams in four strategically located sorting hubs, mobilisation costs decrease by 30% compared to a decentralised approach, thanks to shared infrastructure and improved capacity utilisation.

-

Technology and shifts: Automated sorting becomes cost-efficient at higher volumes and with at least two shifts; manual sorting remains competitive only at low volumes due to its labour-intensive nature.

-

Capacity utilisation is crucial: In practice, only 14% to 28% of theoretical capacity is achieved. Moving closer to theoretical values could reduce sorting costs by 66-75%.

What does this mean for policy and the sector?

The LoF model shows under which logistical conditions sustainable processing of post-consumer textiles in Flanders would be feasible, provided there are policy choices that stimulate demand for recycled material and support centralisation, collaboration, and social employment.

The LoF model is a strategic tool for weighing up scenarios based on costs and social employment. By continuously updating the model with real-world data, market insights, and social ambitions, Flanders can position itself as an international frontrunner in circular textile processing. In this way, the path is paved towards a robust, inclusive and future-proof textile chain.

About Labs on Fibre

Labs on Fibre is a Living Lab within VLAIO – Living Labs Circular Economy, involving partners from the social and non-profit sectors, focusing on high-quality, transparent, and locally anchored processing of post-consumer textiles. Together, we worked on innovative value chain collaborations and partnerships to turn a circular business model for post-consumer textiles into reality.