Port of Antwerp-Bruges and VITO urge action to strengthen circular eco system

Port of Antwerp-Bruges and VITO examined the potential of the Antwerp chemical cluster to incorporate recyclates to replace fossil raw materials. They analysed how the use of recycled and renewable raw materials could be increased, aiming to anchor the Antwerp industrial cluster in a sustainable, resilient, and future-proof manner as a vital part of European industry.

Commissioned by the Port of Antwerp-Bruges, VITO studied the concrete possibilities to replace fossil raw materials that form the feedstock for the Antwerp chemical cluster as much as possible with either bio-based or recycled sources of carbon. To better understand this potential, VITO scrutinised the existing industrial system for the production and recycling of plastics in Belgium, as well as in neighbouring countries.

From mechanical to chemical recycling

The analysis shows that currently, plastic recycling in Belgium is almost exclusively done through mechanical recycling. Although Belgium is the European champion in plastic recycling according to a recent study by Plastics Europe, with a recycling rate of 39%, a significant portion of plastic waste is still incinerated. However, mechanical recycling can only process a limited portion of plastic waste into recycled products. For these limitations of mechanical recycling, the chemical industry provides solutions, both for processing them into new raw materials and for using these raw materials as feedstock for their production processes.

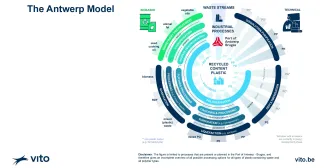

The Antwerp Model

In its study, VITO proposes the Antwerp Model, which aims for defossilisation by replacing fossil carbon sources with renewable sources. As home to the largest integrated chemical cluster in Europe and the main hub for the production, treatment, and distribution of plastic pellets - Antwerp produces 4 million tons of polymers annually - the port is the ideal location to develop a circular hub and take a leading role.

The first steps to develop this circular hub and bring the entire chain together were taken on 18 September during an interactive workshop at the Antwerp Port House. VITO presented the study results, including the Antwerp Model. This was followed by a panel discussion with sector associations essenscia PolyMatters and Cefic, delving into challenges related to policy on one hand and strengths such as the presence of the chemical cluster on the other. All parties emphasised the call for companies to collaborate in forming a cohesive circular cluster.

All partners also strongly believe that despite the challenges, chemical recycling in Belgium holds promise due to significant polymer production, high expertise in waste management, and excellent connections with other clusters and the rest of the world, with the Antwerp port as the ideal circular hub.

"The Port of Antwerp-Bruges plays a crucial role in the transition to a more sustainable economy," said Jacques Vandermeiren, CEO of the Port of Antwerp-Bruges. "By collaborating with VITO and other partners, we can strengthen our port as a center for innovation and sustainability, which is beneficial not only for the environment but also for the economy and employment in our region."

For the future of the Antwerp chemical cluster, collaboration between industry, government, and research organisations is essential to accelerate the transition to a circular economy and defossilisation," says Inge Neven, CEO of VITO. "VITO aims to further support the chemical sector with targeted technological innovations and by providing test facilities and pilot installations. However, today, the demand for chemically recycled raw materials still lags behind due to higher costs compared to primary raw materials. To address this and ensure competitive scale, regulation and supportive measures are indispensable."