Unique 3D printing pilot line marks major step for the chemical and energy sectors

VITO is taking an important step towards the sustainability of the chemical and energy sectors. The construction of an advanced 3D printing pilot line responds to the growing demand from industry for innovative components under industrially relevant conditions. This project is supported by the European Regional Development Fund (ERDF) and the Innovation and Enterprise Fund (FIO).

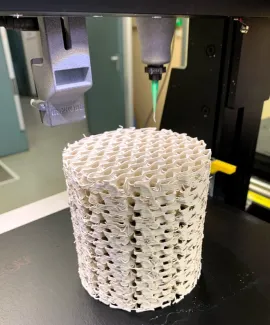

3D micro-extrusion

The project focuses on the construction of a state-of-the-art 3D micro-extrusion pilot line, a technology capable of processing various materials such as metal, ceramics, and hybrid materials. This enables the production of high-quality functional components, such as catalysts, sorbents, heat exchangers, and electrodes through 3D printing, which is crucial for the sustainability of the sector. VITO has already successfully tested this technology at the laboratory scale. Scaling up to a pilot level is necessary to validate the technology under industrial conditions.

One of a kind worldwide

This new pilot line is one of a kind globally and offers companies the opportunity to test the technology in an industrial environment. The pilot line strengthens VITO's position as a knowledge center in 3D printing and promotes co-creation and innovation both in Flanders and beyond. The facility can produce up to one ton of functional components per month in an automated, (semi-)continuous process, marking a crucial step toward market introduction.

European Regional Development Fund (ERDF)

With this investment, VITO takes an important step toward further sustainability in the chemical and energy sectors, providing the industry with new opportunities to implement innovative technologies more quickly and efficiently.

The development of the pilot facility in the 3DPRIME project was approved by the European Regional Development Fund (ERDF) and the Innovation and Enterprise Fund (FIO).