VITO/EnergyVille tool helps port authority select sustainable and circular companies

To make its port climate-neutral by 2050, Port of Antwerp-Bruges is moving towards more sustainability and circularity. NextGen District, a new industrial cluster to be built on the former Opel site, will play an important role in this transition. To make the site as sustainable and circular as possible, the port authority called on VITO's rich expertise in sustainability assessments.

Banner image: Copyright Port of Antwerp-Bruges

If Europe wants to be climate neutral by 2050, it will only succeed if its industry can also become low-carbon by then. In that context, Port of Antwerp-Bruges expressed its ambition two years ago to also be completely climate neutral by 2050. This ambition will be put into practice within NextGen District, which will be built on the former Opel site on the Antwerp platform. This new industrial cluster will be a hotspot of sustainable innovations and circular economy.

Strict conditions

There was no shortage of candidates for a concession at the new site, where earthworks are currently underway that include construction of a sewerage and heat network. Currently, five companies have agreed to come and set up at NextGen District. Or rather, they have been given the green light to do so by the port authority, because to be admitted to the site, prospective concessionaires must meet strict conditions. This is a result of the board's "one hundred per cent focus on circular economy". The circular economy involves thinking and working from closed cycles as much as possible, from the supply of raw materials over production processes to waste management. In line with this focus, the conditions for admission to NextGen District therefore include criteria on sustainability, circularity and climate impact. In addition, more economic and practical criteria are also used, such as added value for the Flemish economy and opportunities in terms of industrial symbiosis with other companies.

In order to be able to evaluate the circular criteria (to summarise them under one denominator) of the proposed projects of the candidate concession holders as objectively as possible, and thus be able to compare them, the port authority called on VITO/EnergyVille. 'Comparing such criteria one-to-one between different projects is a very complex exercise,' says Dries Van Gheluwe of Port of Antwerp-Bruges. 'We therefore consulted VITO, which obviously has a lot of expertise in this.'

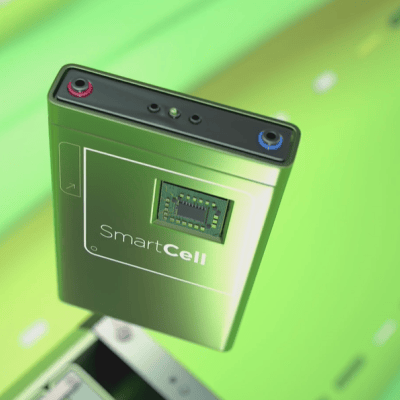

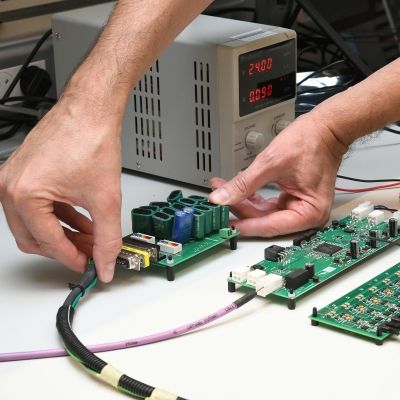

VITO/Energyville developed a sustainability evaluation tool, tailored to NextGen District. The tool essentially screens a project completely in terms of sustainability and circularity. 'We look not only at CO2 emissions (for climate impact) or other harmful emissions (for environmental footprint), but also at more circular criteria such as raw materials, water and land use, waste management, mobility and transport,' says Steven Claes of VITO/EnergyVille. 'Moreover, we also take the indirect impact into account. For example, it is relevant how raw materials are supplied. Is this done by ship, possibly via inland navigation, or perhaps by truck? And are there plans to electrify this transport?' The VITO/EnergyVille tool provides results in the form of sustainability and circularity scores for the activities within a project. 'Take a company specialising in a sustainable insulation material. The tool then calculates, among other things, the climate and environmental cost per tonne of finished product produced, including the transport to get it to the customer, and compares it with a reference product performing the same function (benchmark).'

Wider use

As mentioned, VITO is very familiar with sustainability assessments. In that sense, the development of the tool was not new. 'But we did focus it specifically on the case of NextGen District, which targets companies active in energy supply and in the process industry,' says Carolin Spirinckx of VITO/EnergyVille. For the process industry, the port authority focuses on three subdomains: (re)use of CO2 as a raw material, biomass as a substitute for fossil raw materials and fuels, and recycling of plastics. 'We also took this into account when developing the tool.'

Incidentally, the tool cannot only be used as a decision-making tool by the port authority, but is also interesting for companies to get a better view of their sustainability and circularity performance - they can then take improvement actions based on this. In addition, the tool, or rather the general framework behind it, is also applicable outside the context of a port. Spirinckx: 'Subject to some adjustments, urban planning departments of local governments can also benefit from it. For example, they can use it to optimise their industrial estates.'

The use of the tool, and its wider potential, is a fine example of how VITO/EnergyVille can put its sustainability vision and mission into practice, in the case of NextGen District in a more sustainable and circular port industry.

As mentioned, there was no shortage of candidates for NextGen District. The latest company to be awarded a concession for a site in early 2023 is US-based PureCycle. The facility there will recycle plastic waste (polypropylene). This will be done through an innovative process that allows repeated recycling and thus reuse. PureCycle is the fifth company on the site, immediately filling in half of the site - the part that was given in concession.