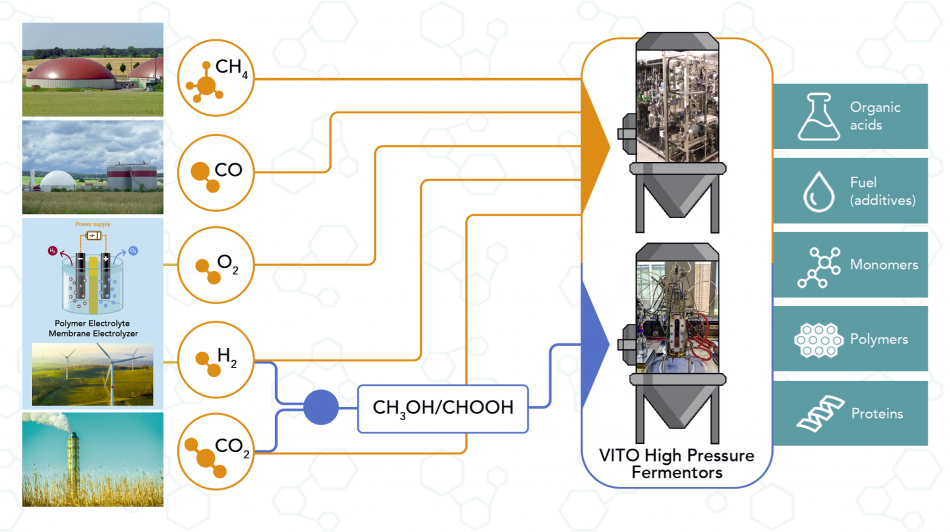

Gas fermentation is a technology that uses micro-organisms to convert gaseous feedstocks such as carbon monoxide (CO), carbon dioxide (CO2), syngas, methane (CH4), or biogas, into platform chemicals, fuels, polymers, etc.

In contrast with traditional fermentation, the bioconversion process relies on microorganisms that are able to use carbon-rich gases rather than sugars or organics as substrate. For certain applications, the technology has already reached semi-commercial scale.

Your benefits

Bioconversion processes have advantages compared to chemo-catalytic or thermochemical ones:

- milder environmental conditions

- higher conversion efficiencies

- higher product specificity or selectivity

- lower sensitivity to variations in gas composition

- higher tolerance to impurities which are known to poison inorganic catalysts

Our offer

- Access to equipment and knowhow for gas fermentation, including bioprocess design, engineering and optimization

- Access to knowhow on process intensification, in particular on integration of bioprocesses with membrane separation technology for biocatalyst retention or in situ product removal

- The techno-economic feasibility of different applications can be evaluated in proof-of-concept and validation studies

VITO’s equipment and expertise for gas fermentations are of interest to:

- companies aiming to valorize their carbon-rich gaseous emissions

- companies active in biocatalyst development

- technology developers or suppliers

- companies looking for alternative feedstocks

Why work with VITO?

Adequate equipment and infrastructure

- Gas fermenters (up to 10 L working volume) for operation at atmospheric and elevated pressure (up to 10 bar), equipped with flexible gas supply and online gas monitoring and control, and ATEX compliant.

- Lab certification/permit for work with GMOs

Expertise and knowhow

- >10 years of experience with gas fermentation processes, including tests with real offgases

- Experience with single- and multistage fermentations (e.g. heterotrophic-autotrophic concepts)

- Knowhow on optimization of mixotrophic processes combining the supply of a gaseous C1 feedstock with an organic co-substrate

- Extensive knowhow on design, engineering, operation and optimization of fermentation processes in batch, fed-batch and continuous mode

- Broad experience with stand-alone fermentations as well as set-ups, coupled with separation technology

- Phased trajectory from proof-of concept to feasibility studies at lab-scale

- Support for pilot-scale tests

- Techno-economic assessment of results

- Strong network in the area of Carbon Capture and Utilization