INNOMEM: Open INNOvation Test Bed for nano-enabled MEMbranes

VITO’s role

Upgrade Demo FunMem synthesis installation + demonstration of FunMem capabilities in Showcase icw LiqTech. Perform possible other demo-cases coming in via SEP. WP1 leader (upgrading all pilots).

Project partners

Tecnalia l TU/e l ITM-CNR l UNIZAR l Imperial College l Aston Univ. l Fraunhofer IKTS l HZG l FORTH l Univ-Montp l Univ-Twente l Uni-DUE l RWTH l Demokritos l LiqTech l Polymem l DBI-GUT l FURTHR Research l SUK l HTFM l ECOTECH l Filatech l Rauschert l Ciaotech l Evonik l Engie l Hydrogen Onsite l Me-Sep l Tecnalia Ventures l UNE l NX Filtration

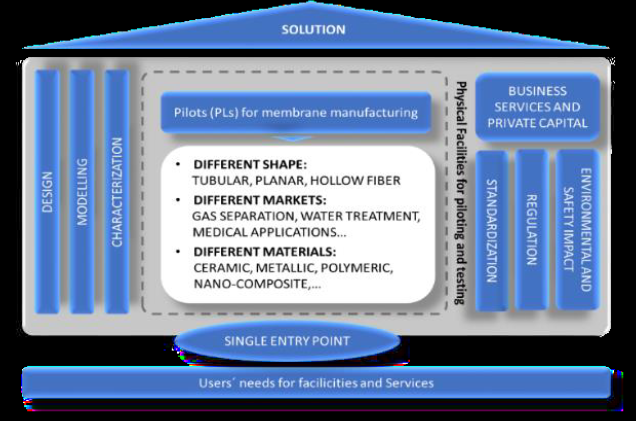

Abstract

INNOMEM gathers some of the most recognized Membrane departments (>20) in Europe and acknowledged facilitators of technology transfer, corporate finance, funding and coaching, making available (i) the most promising and breakthrough manufacturing pilots and (ii) advanced characterization techniques and modelling together with (iii) non-technical services through this Test Bed. The potential network of reachable stakeholders counts thousands of businesses on an international scale. Within the scope of INNOMEM, main different types of membrane materials (polymeric, ceramic, metallic and nanocomposite), surface modification, membrane morphology and geometry and applications will be covered, providing for the first time a single entry point for industrial partners, mainly SMEs, aspiring to answer their concerns, but with minimum investment costs and reduction of risks associated with technology transfer, while opening-up opportunities for demonstration of innovative nanomembranes in real life industrial problems (TRL7) and thus faster opening the market for these new products.

The main KPIs for INNOMEM:

- Technical: 20% Membrane productivity improvement, 30% faster verification, >40% CO2 emissions and energy consumption reduction.

- Non-Technical: 10 Showcases, >15 Democases, >100 reachable SMEs and > 300 reachable investors.

INNOMEM stems from the consideration that the development of products based on advanced membranes and nanomaterials require access to finance and an optimized business planning, relying on a sound prior analysis of the market, of the economic impacts and capacity of a company. The project aims at developing and organizing a sustainable Open Innovation Test Bed (OITB) for nano-enabled membranes for different applications. The OITB will also offer a network of facilities and services through a Single Entry Point (SEP) to companies (inside or outside Europe).

Development and characterization of Silicon Carbide (SiC) membranes for innovative applications

Vito's role

VITO will study the feasibility of SiC filtration for a challenging application of CARBOGEN AMCIS, using both native and grafted membranes. Furthermore, grafted membranes will be supplied to other partners for testing in other applications.

Project partners

Shell Global Solutions l ESD-SiC l LiqTech l Semco Maritime l Carbogen Amcis l Aramco Overseas Company l Friesland Campina l Wageningen Food & Biobased Research l KWR Watercycle Research Institute l University Twente l ISPT

Abstract

The separation of oil from stable oil in water emulsions is a challenge, especially if low limits for oil in water are required as in the case of produced water (< 30 ppm dispersed oil). Many technologies have been studied, but proved to be technically or economic challenging (energy demand, need for additional materials,etc.) Ceramic membrane filtration proved to be an interesting option. Boundary condition is that the membranes can be operated and cleaned at rather extreme pH and temperature conditions. The existing zirconia or alumina membranes have a limited pH resistance and exhibit extensive fouling tendency under certain conditions. Silicon Carbide (SiC) does not have these limitations. In previous projects (e.g. CombiClear) it is shown that the SiC membranes show a good performance for the treatment of oil in water emulsions. Still missing is the behavior of these membranes at duration tests and in particular cleaning possibilities of these membranes. This will be studied in this project during a pilot trial, where fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics will be determined (TRL 7).

Because SiC membranes are very robust, it is interesting to extend their applicability to other domains, e.g. food, dairy, pharmaceuticals, chemistry. In this project the potential of the SiC membranes for several of these applications will be studied on small scale (TRL 3-5) and will provide the performance of these membranes for these applications (flux, separation factor, etc.). Because these other applications require partly different types of separation characteristics of the SiC membranes, the existing UF/MF range of SiC membranes will be extended to the nanofiltration (NF) range by the development of more dense coatings (TRL 3-4). The project as a whole will deliver a good assessment of the feasibility of the SiC membranes, it will extend their feasibility to new applications and sectors, and derisk the technology with duration tests for challenging separation of stable oil in water emulsions, such that SiC membrane technology will be ready for large-scale deployment.

Watch: plastic Waste To Chemicals

VITO’s role

- Explore potential, demonstrate applicability and identify challenges of downstream separation and purification, considered a key enabling technology for chemical plastics recycling

- Design tailored processes, primarily based on advanced membrane separation, for recovery of target compounds from plastic oil, prior to or after catalytic upgrading

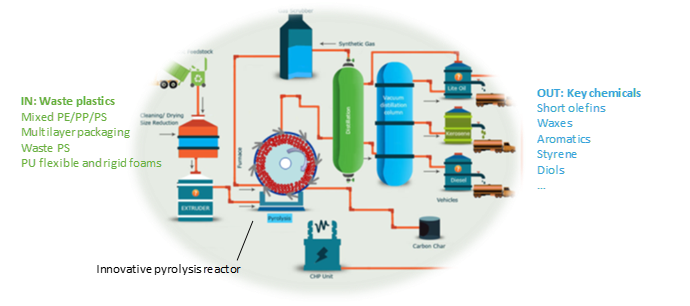

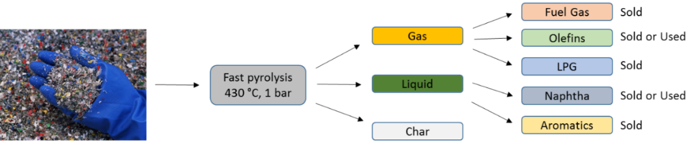

Abstract

WATCH aims at the development and demonstration of a new disruptive technology for conversion of plastic waste to chemicals via catalytic fast pyrolysis based on an innovative reactor concept. The latter technology will be benchmarked against classic, state-of-the-art pyrolysis technology and a sustainability assessment will be performed. Four relevant plastic waste streams which can today not be easily recycled mechanically, will be studied, i.e. mixed polyolefins, multilayer packaging, polystyrene and polyurethane.

Besides kinetic modelling and reactor engineering, focus will be given to optimal feedstock selection to optimize individual yields of desired product(s).

Next to reactor technology, novel catalyst systems will be developed to catalytically convert pyrolysis oil fractions into valuable, well-defined chemicals and liquid energy carriers with lower or comparable production cost in order to (partially) replace their petrochemical counterparts.

Downstream of the pyrolysis process itself, focus will lie on the replacement of classical thermal processes such as distillation by more efficient processes, especially membrane filtration, for separation of valuable components. As such a significant cost-saving and reduction in CO2 emissions could be achieved.

EASiCHEM: Efficient Affinity Separations for Chemical Applications

VITO’s role

Develop and understand membrane-based extraction with tight functionalised ceramic membranes. Benchmark to membrane extraction with open membranes, nanofiltration and L-L extraction.

Project partners

Advisory board

Abstract

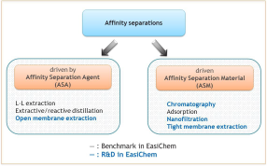

Many chemical companies are nowadays confronted with very challenging liquid separations, aiming at separating molecules with very similar physical properties. The current trend towards more bio-based and/or highly-tailored chemicals, will only increase the number of these demanding separations. These challenges would benefit from efficient Affinity Separations (AS).

The most traditional AS technology is liquid-liquid extraction, where the extracting solvent acts as the separation agent (ASA). The most selective AS is liquid chromatography, driven by the affinity between molecules and a functionalised stationary phase, the separation material (ASM). Although successful in different situations, both AS processes have important drawbacks.

EasiChem aims at tackling these limitations, by developing more efficient, and/or more sustainable AS processes, focusing on two promising, energy-poor liquid separation technologies:

1.Membrane-based AS processes : bringing the selectivity of chromatography to membrane separations, using functionalised ceramic membranes tailored to match the separation problem;

2.Continuous chromatography : tackling the main disadvantage of selective chromatography, making use of a membrane-contactor-like design at microreactor scale.

Lignocost: establishment of a Pan-European Network on the Sustainable Valorization of Lignin

- Leader of Working Group 3: Industrial application requirements versus lignin properties

- Make an inventory of relevant applications in which lignin (derivatives) can be used to substitute fossil-based compounds, and of the required technical specifications

- Identify promising lignin product-resource combinations, extract structure-property relationships and address “white-spots” in knowledge and technology for further innovation

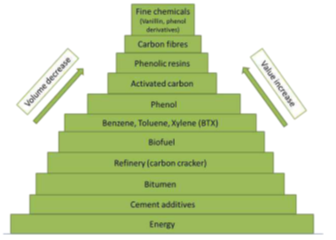

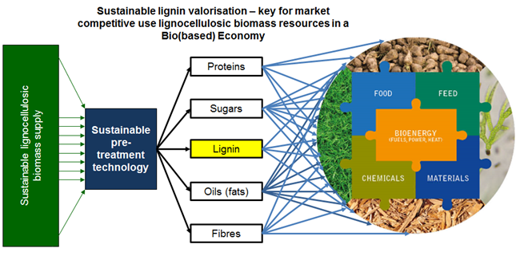

Abstract

Lignin has the potential to become an important future aromatic raw material for the industry, but is largely underexploited due to lack of (information on) industrial availability, sustainable applications, environmental footprint. Economic considerations nonetheless make its valorization mandatory for the viability of future biorefinery operations. To facilitate the transition of a complex, highly underexploited side stream to a major biorefinery product and industrial commodity raw material, a European network is established to join and coordinate the many efforts underway in academia and provide industrial stakeholders including SMEs relevant and up-to-date information on lignin.

Topic covered include:

- WikiLignin database comprising lignin sources, availability, properties and repository of state-of-the-art analytical methodologies and turn key methods for industry

- Bio- and chemo-catalytic conversion technologies including technology readiness level (TRL) assessment

- Industrial application requirements (market demand) versus lignin properties (supply)

- Development of value chains for lignin valorization

- Technical and full sustainability aspects, LCA, market potential and implementation.

From different disciplines this LignoCOST Action brings together industrial stakeholders, SMEs, academia and institutes from pan-European regions active in the pulp & paper, agrofood, biorefinery, chemicals and plastics, infrastructure and construction, fuels and energy, and consumer products industries. The main objective of LignoCOST is to establish a sound network covering the entire value chain in which relevant information can be produced with a focus on lignin valorisation towards sustainable industrial applications. Only when working together this information can be gathered to cover the technical, non-technical, environmental and socio-economic implications of the most promising lignin value chains.

Bregilab

VITO's role

Techno-Economic Assessment of power-to-gas systems.

Project partners

Abstract

Given the fact that there is a major peak in solar energy around noon, the current injection into the grid must be limited when there is a lot of sun to prevent overloading of the electricity grid. In a short internal study by EnergyVille it was already established that, with an injection limit on solar panels, 50% of the electricity production can be generated via wind and sun without overloading the grid or without the need for batteries. With the installation of an optimal extra battery capacity, up to 70% renewable electricity can be used without putting extra strain on the grid.

The BREGILAB project will examine in detail how this can be practically realized at minimal cost for network expansion and batteries. The following topics are being studied:

- Design of the electricity grid for maximizing the direct consumption of renewable energy with a grid injection limit

- Optimal geographical distribution of the capacity of wind turbines

- Optimal geographical distribution and orientation of solar panels

- Optimal dimensioning and spreading of storage, for instance with batteries

- Use of surplus renewable energy for thermal industrial processes

- Impact of the growth of electric cars and heat pumps on the electricity grid

In this way, the BREGILAB project forms an essential element to prepare Belgium for the further rollout of solar and wind energy in the coming decades.

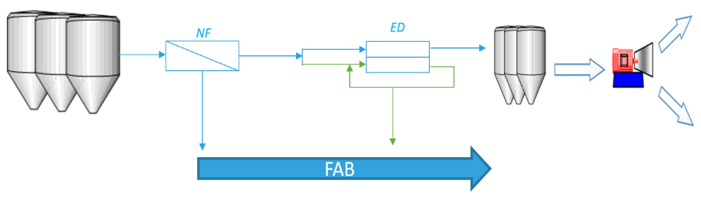

Valorization of citric acid side streams to high value coproducts

VITO's role

Improvement of betaine over dry matter ratio of one of the existing co-products coming from the production of citric acid by using two different membrane technologies: nanofiltration and electrodialysis. Extensive laboratory studies and pilot demonstrations.

Abstract

The overall goal of Citrique Belge is to use separation techniques (i) to reduce the losses of citric acid in the by-products, (ii) to improve the functional properties of the by-product Citrocol, and (iii) to achieve more sustainable downstream processing. This requires a thorough and substantiated redesign of the current FaB processes. This project must generate the necessary knowledge that such restructuration will enable in the long term. The major impact of these changes on the current process, infrastructure and quality of the new co-products immediately indicates the challenging nature of this project proposal.

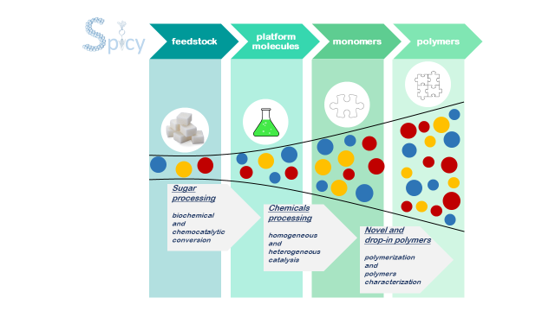

SPICY: sugar-based chemicals and polymers through Innovative chemocatalysis and engineered yeast

VITO's role

VITO investigates innovative in-situ product recovery approaches for the yeast-based fermentation processes.

Project partners

Abstract

The main aim of SPICY is to provide chemical industry with new or optimized processes to convert sugars into added value compounds, i.e. both drop-ins and novel biobased chemicals. Two complementary lines are hereto developed in parallel, one focusing on biotechnology based on improved yeast strains and one based on chemocatalytic routes. Both will aspire to meet industrial standards of productivity, titer, yield and selectivity, to safeguard potential economic benefit and future industrial valorisation. Most of the targeted platform chemicals are (potential) monomers for biobased plastics, hence, a second aim of SPICY is to deliver proof-of-concept of their usefulness by targeting novel and functional polymeric materials, typically not found in the current oil-based value chain.

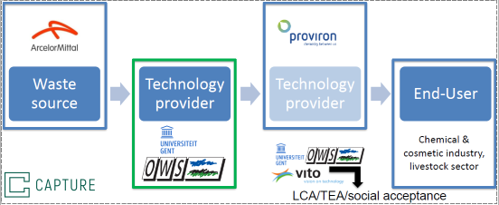

Capra: upgrading steel mill off gas to caproic acid and derivatives using anaerobic biotechnology

VITO's role:

Techno-Economic Assessment

Project partners

Abstract

One of the greatest challenges of the 21st century is the drastic reduction of greenhouse gas (GHG) emissions to the atmosphere to minimize/mitigate the impact of global climate change. In this context, the possibility to capture CO2 at point sources, which account for 45% of the emissions in Europe, and transforming it into added-value products, is gaining attention. The steel industry sector is one of the largest GHG contributors. In their strive for GHG emission reduction, strategies such as improvements in energy efficiency, resource recycling, utilization and recovery have already been implemented, but further emission reduction can only be achieved by capturing CO2 emissions. Valorisation of CO2 into chemical building blocks is possible through biological or chemical processes. Biotechnology is in particular a very interesting way to valorise these waste gases due to their low energy requirements and mild reaction conditions. Traditional disadvantages of biotechnology, such as low yields, low substrate affinity and low selectivity have been overcome in recent years.

ArcelorMittal is exploring the use of syngas fermentation technology as part of the CO2 emission reduction strategy. Many fermentation processes are focusing on the fuel market to take off their fermentation products, and are facing a low revenue from the end products, which sometimes require an energy-intensive distillation process to meet the quality standards. The CAPRA technology developed by OWS and UGent is offering an alternative to avoid this expensive distillation, and turns the fermentation products into a high value chemical. Ethanol/acetic acid mixtures can be transformed to medium-chain carboxylic acids by biological chain elongation, resulting in a bio-oil with higher value (more than double) compared to fuel. This bio-oil, composed mainly of caproic and caprylic acid, can be further processed in the chemical industry as evaluated by Proviron. The environmental sustainability and economic feasibility is evaluated by UGent, OWS and VITO.

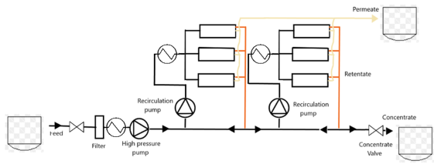

Solvent tolerant nanofiltration

VITO’s role

- Systematic lab scale testing of developed membranes on synthetic model mixtures, incl. development of standardized test protocols, benchmarking against commercial membranes and data acquisition for membrane/process model

- Pilot testing of selected membranes/modules on real industrial streams under relevant conditions, evaluation of longer term performance and robustness, development of cleaning protocols

Abstract

Many industrial process streams contain both water and solvents, in addition to other organic components. Such streams need to be purified from these components or be treated before further processing, discharge or incineration. Polymeric nanofiltration membranes nowadays widely used in (waste)water treatment typically exhibit high permeability and stable rejection. They offer a more sustainable and energy efficient alternative to currently used conventional separation technologies. However, if a solvent is present in the aqueous feed stream, these performances are often lost due to phenomena like swelling and membrane degradation. This behavior proves to be a major obstacle, hindering widespread implementation of membrane technology in water/solvent streams.

This project aims to tackle this challenge by development of new, robust nanofiltration membranes with competitive performance in a wide range of solvent/water mixtures and able to separate and substantially concentrate small organic compounds from such streams. The membranes will be tested on various relevant industrial process and waste streams, and benchmarked against commercial nanofiltration membranes. The most promising candidates will be tested at pilot scale to demonstrate long term robustness and performance. A data driven model will be created to identify critical process parameters and predict membrane behavior under industrial conditions. A techno-economic evaluation of the test cases will be made, as well as a roadmap for implementation of promising membranes after the project.

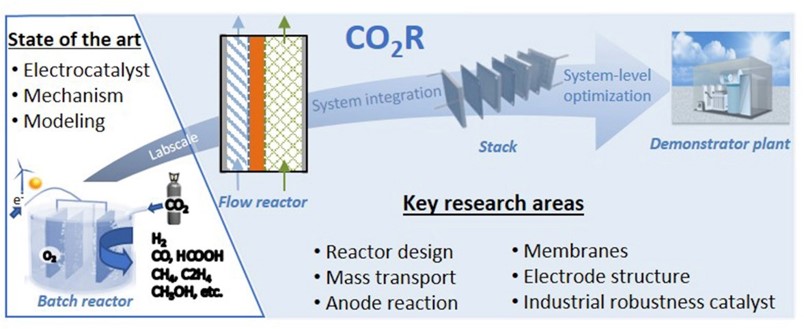

Electrons to High Value Chemical Products

VITO's role

VITO is involved in the direct conversion process of CO2 within the work packages “enabling research” and “demonstration systems”. VITO is responsible for the integration, development and testing of newly synthesized electrocatalysts into gas diffusion electrodes. Moreover, VITO supports in the design, manufacturing and operation of the demonstrator system of direct CO2 conversion to formic acid.

Project partners

Abstract

The coastal areas of the 2 Seas region combine (future) availability of renewable energy with strong industrial activity. This leads to the common challenge of handling renewable energy surpluses, diversifying feedstocks in the chemical industry, reducing greenhouse gas emissions in energy intensive industry, and meeting societal and regulatory demands on advanced fuels and sustainable chemicals. "Power-to-X” concepts, using (renewable) electricity as a replacement for oil and gas energy sources in the production of chemical products, allow for the combination of a solution to these challenges with the creation of valuable products. However, several technical and economic hurdles still need to be overcome. These are related to the cost of renewable hydrogen, the technological immaturity of novel electrochemical processes, and the need for demonstrators and business case calculations to convince industry to invest in further development and implementation of these technologies.

Sustainable membrane technology-based solutions for solvent-rich wastewater treatment

VITO’s role

Development of (hybrid) membrane processes + proof of concept and pilot demonstrations

Project partners

Abstract

Since 1 November 2017, the research project SuMems, initiated by the pharmaceutical companies Janssen and Ajinomoto Bio-pharma services (former Omnichem) and the OEM company InOpsys, is running in the framework of the Catalisti program “valorization of side streams”. The project works on the development of innovative membrane-based solutions for the sustainable and economic treatment of the typical solvent-rich, and often very alkaline waste waters, that are currently incinerated externally. Optimal (hybrid) processing will allow to recuperate valuable components as precious metals or metal catalysts, and to send the purified waste streams to the existing on-site wastewater treatment plants.

Research partners VITO and KULeuven identified suitable membranes and membrane processes for the dehydration of salty Non-Recyclable Solvent streams (NRS), and for the Pd removal from a strongly alkaline water-based waste stream and from a methanol-based mother liquor. Pervaporation with hydrophilic ceramic membranes proved to be very efficient for the treatment of NRS streams. The alkaline wastewater streams can be efficiently purified by nanofiltration with an alkaline resistant polymeric membrane (HydraCore or MPF-34), while a functionalized ceramic nanofiltration membrane of VITO (FunMem®) turned out a very good membrane for the metal removal of the methanol mother liquor.

All efforts are dedicated to the preparation of three piloting campaigns at the industrial partners, using the existing pilots at Janssen and VITO. Based on these larger-scale experiments, the robustness of the processes and the value of the retentate streams can be properly assessed, while the business cases can be properly evaluated.

Further research in the project is focused on generating generic data, allowing to define a workable decision tree for the membrane-based (hybrid) treatment of similar challenging waste streams.

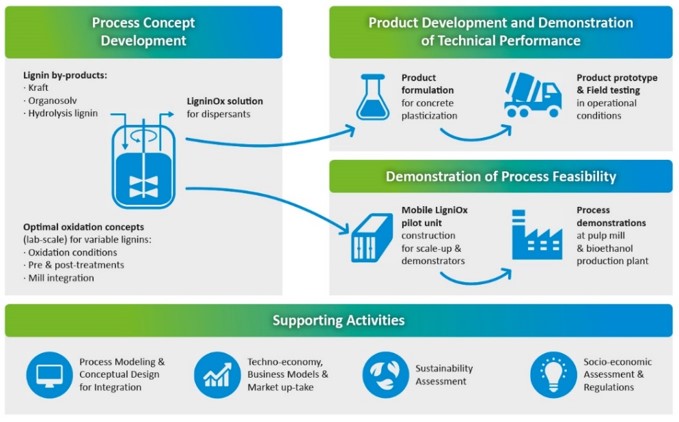

Lignin Oxidation technology for versatile lignin dispersants

VITO's role

- Post-treatment of oxidized lignin using membrane filtration, targeting enhanced plasticizer performance, improved applicability and recovery of process chemicals

- Design and pilot scale demonstration of integrated membrane processes tailored to various oxidized lignin types, considered essential for techno-economic feasibility of overall LigniOx technology

Consortium

Abstract

The aim of the LigniOx Innovation Action is to demonstrate the techno-economic viability of alkali-O2 oxidation technology (LigniOx) for conversion of variable lignin-rich side-streams into versatile dispersants, especially high-performance concrete and mortar plasticizers.

Both the oxidation technology and end-product performance will be demonstrated at operation conditions, enabling industrial process installations and entry of novel lignin products into the market after the project, replacing current synthetic superplasticizers and lignosulphonate products. The versatile LigniOx technology can be integrated into lignocellulosic biorefineries, or be operated as a stand-alone unit by chemical industry. The valorisation of lignin side-streams will significantly improve the cost-competitiveness and resource efficiency of lignocellulosic biorefineries, while creating low-cost, sustainable raw materials for the chemical industry.

The most prevalent techno-economic concepts for industrial process installations will be defined. Oxidation conditions will be optimized for variable lignin raw materials, and post-treatment based on membrane technologies will be developed, to meet the requirements of target end-product.

A mobile pilot unit will be constructed for scale-up and process demonstrations at biorefineries. The viability of the process concepts will be demonstrated in operation conditions at kraft pulp mill and other biorefineries. Conceptual design will be performed to ensure proper integration of industrial LigniOx processes at the biorefineries or operation in stand-alone units.

Implementation of Solvent Recovery in edible Oil industry

VITO’s role

- Development of modified ceramic membranes for selected application cases , incl. scale-up of selected membranes

- Design of efficient separation protocols through lab scale testing of both ceramic and polymeric membranes

- Pilot testing of selected membranes/modules on real industrial streams under relevant conditions, evaluation of longer term performance, robustness and cleanability

Project partners

Abstract

Organic solvent nanofiltration (OSN) is an emerging technology that is recognized for its facilitation perspectives of recycling organic solvents in industrial processes. In the former project EEMBAR, it was found through on site pilot trials at IOI Loders Croklaan that OSN has the potential to reduce the energy requirements of the distillation based acetone recovery process by about 50%. Although a proof-of-principle was shown using spiral-wound elements of SolSep, the difference between small scale experiments in the lab and piloting was found to be larger than anticipated. Scale-up challenges are assumed to arise from the specific nature of the vegetable oil as well as the relatively high oil concentrations the membrane should handle, and their impact on mass transfer. As there is a clear outlook that this concept can be optimized to a satisfactory solution in the industrial environment (TRL 7), specific developments in module design will be addressed.

To further demonstrate the viability of OSN for solvent recovery from edible oils and leverage the advancements in membrane/module design, a second industrial process will be studied, i.e. the reuse of high boiler solvent from a cleaning solution in a plastics recycling process at TUSTI. In addition to polymeric OSN modules, tailored functionalized ceramic membranes will be developed by VITO and tested on both cases.

The result of the project is the proof-of-principle of OSN-based solvent recovery for both application cases, which will be studied through on site piloting on real industrial oil/solvent mixtures. A successful integration of OSN with the current distillation process will make recovery of acetone at IOI Loders Croklaan significantly less energy intensive, while also offering the opportunity to flexibly enhance capacity at a lower cost and smaller footprint. For TUSTI, recovery of spent high boiler solvent by OSN would allow direct reuse in the cleaning process, bring significant savings in transportation costs while also making the biodiesel process more efficient.

Microbial electrosynthesis

- Carbon conversion to chemicals by microbial electrosynthesis

- To develop the MES technology to pilot level using joint resources of VITO and Indian Oil R&D Centre

VITO’s role:

- Development of specialized gas diffusion electrodes for MES

- Exchange of knowledge on reactor design and upscaling for MES

- Hosting Indian Oil researcher at VITO

- Visiting Indian Oil facility for knowledge sharing

Abstract

In recent years, various approaches for capturing and transforming CO2 to value-added chemicals has been developed among which microbial electrosynthesis (MES) is one of the vibrant technologies that can utilize the renewable energy from solar or wind to transform CO2 into value added products. Microbes that are capable of exchanging electrons with solid electron acceptors and have ability to accommodate CO2 into their metabolic pathways catalyze this reaction. There is a need of developing selective culture that has capability to produce higher organics. In this project, selectively enriched mixed culture will be developed for an efficient MES. The project will also explore the application of gas diffusion electrodes (GDEs) for the CO2 transformation to alcohols in MES. The final goal of the project is to build and operate a pilot MES reactor.

CO2PERATE - techno economic assessment

VITO's role

Techno-economic assessment and decision support framework

Project partners

Abstract

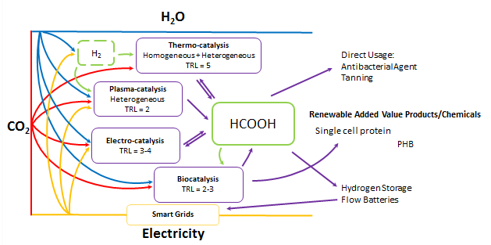

The 2030 framework for climate and energy policies contains a binding target to cut greenhouse gas emissions in EU territory by at least 40% below 1990 levels by 2030, and has the ambition to further reduce them by 80-95% by 2050. As theoretical limits of efficiency are being reached and process-related emissions are unavoidable in some sectors, there is an urgent need to develop efficient carbon capture and utilisation systems.

The main objective of the project is the development of technologies for the conversion of CO2 to value-added chemicals using catalysis and renewable energy. To benchmark, compare and develop the various technologies, the formation of formic acid was selected as the initial target. In the project, the development of 4 catalytic routes (homogenous & heterogeneous catalysis, photochemical plasma-catalysis, electrochemical catalysis and bio-catalysis) is planned, enabling the sustainable synthesis of formic acid and more complex value-added chemicals (Single Cell Proteins, etc.). Sustainability is the common denominator of the different routes investigated in the project. A decision support framework will be developed to support the selection of the best technology given a specific situation(CO2 source, purity and intended product, availability of excess electricity). Via a techno-economic analysis, the different catalytic routes towards formic acid will be benchmarked against each other and against the classical process via base-catalyzed carbonylation of methanol.

This project has the ambition to strengthen the position of Flanders in terms of research into CO2-based processes and materials. The relevance of this cluster SBO project is further emphasized by an industrial advisory board, who are eager to implement the results and create economic valorisation. Current members of the advisory board include: 3M, Alco Biofuel, Arcelor Mittal, Avecom, Borealis, Cargill, Eastman, ENGIE Laborelec, Hydrogenics, INEOS, Messer, Monsanto, Nutrition Sciences and Smart Bioprocess.

CO2PERATE

The main objective of the project is the development of technologies for the conversion of CO2 to value-added chemicals using catalysis and renewable energy.

VITO is involved in developing the electrochemical conversion route from CO2 to formic acid apart from the techno-economics of the process.

Project partners

abstract

The main objective of the project is the development of technologies for the conversion of CO2 to value-added chemicals using catalysis and renewable energy. To benchmark, compare and develop the various technologies, the formation of formic acid is selected as the initial target.

The first major objective is the formation of formic acid out of CO2 and renewable H2. To this end, 3 different catalytic technologies will be developed. At the end of the project, the project partners want to be able to select the best technology for a certain context (CO2 source, purity and intended product) for the conversion of CO2. A decision support framework will be developed to support this decision process. Via a techno-economic analysis, the different catalytic routes towards formic acid will be benchmarked against each other and against the classical process of formic acid production via base-catalyzed carbonylation of methanol.

The second major objective is the valorization of the produced formic acid. On the one hand, formic acid will be used as a building block for the bio-catalytic production of value-added chemicals such as single cell proteins. On the other hand, the use of formic acid as a hydrogen carrier will be evaluated. When utilizing the H2 upon conversion of formic acid, CO2 is released which can be used again in combination with a new supply of H2 for the formation of formic acid according to a true circular approach.

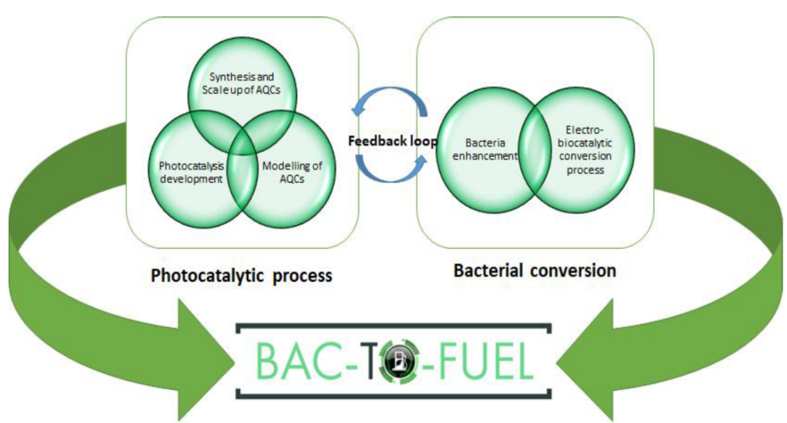

Bac-to-Fuel: bacterial conversion of CO2 and renewable H2 into biofuels

VITO will develop the electro-biocatalytic conversion of CO2/H2 into fuels using genetically modified bacteria from WUR and photocatalytic hydrogen generation system from TUB.

Project partners

Abstract

BAC-TO-FUEL will respond to the global challenge of finding new sustainable alternatives to fossil fuels by developing, integrating and validating a disruptive prototype system at TRL5 which is able to transform CO2/H2 into added-value products in a sustainable and cost-effective way which:

1) mimics the photosynthetic process of plants using novel inorganic photocatalysts which are capable of producing hydrogen in a renewable way from photocatalytic splitting of water in the presence of sunlight

2) uses enhanced bacterial media to convert CO2 and the renewable hydrogen into biofuels (i.e. ethanol and butanol both important fuels for transport) using a novel electro-biocatalytic cell which can handle fluctuations in hydrogen and power supply lending itself to coupling to renewable energy technologies

BAC-TO-FUEL is a multidisciplinary project which brings together leaders in the fields of materials chemistry, computational chemistry, chemical engineering, microbiology and bacterial engineering. BAC-TO-FUEL will validate a prototype system at TRL5 which is able to transform CO2/H2 into added-value products in a sustainable and cost effective way specifically for the European transport sector.

P2C: power to chemicals - ammonia synthesis

- The design of a process for the production of ammonia from air/N2, water and electricity

- The development of a practical electrode for the demonstration of the electrochemical synthesis of ammonia with current density of at least 0.1 mA/cm2 and faradaic efficiency of at least 10 %, which corresponds with the current state-of-the-art

- The development of a plasma process for NH3 synthesis with an energy input of < 30 MJ/mol and NH3 yield of > 1%

Abstract

The overall aim of this project is to demonstrate CO2-neutral ammonia production by renewable electricity-driven processes via a novel electrocatalytic and plasma-based conversion of N2 (Nitrogen reduction reaction, NRR).

Other objectives of the project are:

To reveal the mechanism of N2 activation in candidate electrocatalysts and to screen and rationally develop highly efficient electrocatalysts for NRR. Moreover, investigation and optimization of extrinsic parameters for durable NRR performance as well as investigation and development of plasma reactors for NH3 production

At last development of a stand-alone electro- and plasma reactor driven by a photovoltaic solar cell.

People are becoming increasingly aware that good air quality also guarantees a better quality of life. Correctly measuring this air quality is therefore crucial for implementing suitable measures. In its Sensor Testing and Validation Centre, VITO studies the quality of small, cheap sensors and develops calibration models to make the results of the measurements from these sensors even more reliable.

Our healthcare is of a very high quality and accessible to all. Due to rising rates of chronic diseases, costs are increasing annually, and this is putting pressure on the healthcare system. Policy and technology must be combined to ensure sustainable solutions to enable us to continue to provide the best healthcare to everyone in the future. This transition is possible if we are successful in keeping people healthy for longer. The emphasis is therefore increasingly being placed on prevention and early diagnosis. The earlier we can detect a condition, the sooner we can intervene and prevent that condition from becoming chronic. Trans Tech Diagnostics (TTD) is therefore focusing entirely on the detection of early-stage biomarkers in the form of extracellular vesicles (EVs).

Extracellular vesicles (EVs) are the keys to future healthcare, as they make it possible to diagnose complex diseases such as cancer and Alzheimer’s disease more quickly and more accurately. EVs are microscopic particles secreted by both healthy and diseased cells. They contain a variety of biomolecules such as proteins, lipids, and DNA/RNA, originating from the cell that produced them. They are found in all bodily fluids and circulate throughout the body. As they are able to transmit certain molecules, they act primarily as ‘messengers’ between cells.

airQmap is a powerful platform that allows people with limited or no air pollution expertise, such as city personnel or volunteers, to carry out air quality measurements and to get a detailed view on the air quality at street level. This approach allows for the production of air quality maps at a feasible cost for cities and municipalities.

Citizen scientists train artificial intelligence to detect eye diseases