An adapted biorefinery approach to wet insect biomass to generate multiple compounds suitable for food, feed, and technical applications.

Sharepair

The project addresses the increasing amount of waste from electrical and electronic equipment (WEEE). WEEE is one of the fastest-growing waste streams in the EU, growing at 3-5% a year. Consumption of electrical and electronic equipment (EEE), and therefore production of WEEE, is very high throughout the NWE region (Eurostat 2016, EEE products put on the market). At the same time, NWE is home to a growing citizen repair movement (10,000+ volunteers), attempting to fight back against this upsurge in waste. However, their impact remains small, even though consumers indicate a high willingness to repair. Hence, there is a large gap between intent and actual behaviour, due to a lack of convenient and accessible repair solutions.

The project aims to decrease WEEE from consumer products by scaling up citizen repair initiatives through the use of digital tools: digital tools that stimulate and facilitate citizen repair by collecting repair solutions and making them easily accessible to citizens. The tools will target both consumers at home and more skilled repairers in repair cafés. They will also map and guide citizens towards high-quality professional repair services, and assemble, with the help of designers, a database of 3D-printing designs (open-source) for printing replacement parts.

Project focus

The project focuses on increasing material re-use through repair, in the sector of electrical and electronic equipment (EEE). The project aims at decreasing the amount of waste from EEE (WEEE) in NWE by increasing the rate of repair of these products, thereby extending the product life times. Within EEE, the project focuses on the following product categories (as defined in Annex I of Directive 2012/0019/EU): large household appliances, small household appliances, IT and telecommunications equipment, consumer equipment, lighting equipment, and electrical and electronic tools.

The project distinguishes itself from existing practices by focusing on an underused lever to reduce waste: empower citizens to repair broken products. It aims to harness the experience of citizens, both consumers at home and more skilled repairers in repair cafés, to collect repair solutions and make repair solutions more broadly available, thereby enabling more citizens to engage in repair, whether on their own, together (in repair centres), or with the help of professional repair services. At present, repair information is scattered. It is not being collected or presented in a structured way. The project aims to change this by developing digital support tools that capture and disseminate best practices. These will be structured in a user-friendly way, guiding users along the ‘decision tree’ toward repair (i.e. diagnosing the problem; instructing users on how to fix it; if they cannot fix it themselves, guiding users toward professional services; telling users which replacement parts are needed and where to find them; etc.).

The project’s main output is an integrated approach to scaling up citizen repair. The approach rests on developing a digital infrastructure consisting of five interconnected digital tools:

- a support tool for repairers in repair clubs and repair centres;

- a guidance tool for consumers in households;

- a tool for mapping repair facilities and repair services in the participating regions and cities, with a particular focus on local commercial firms with high-quality services;

- a tool for collecting and sharing open-source designs for 3D printing of spare parts;

- an integrated data space that gathers all the data captured by the above tools and uses ‘big data’ analytics to deliver customised reports indicating, for example, how to improve the effectiveness of the tools based on user behaviour, or how to gear policy and business toward repair.

When completed, this will be the first integrated digital approach to repair in Europe, that will be structures around a joint open repair data platform.

To achieve this, multiple pilots and investments are envisaged. The support tool for repairers will be co-developed with at least 100 repair clubs, who will catalogue at least 10,000 images of broken and repaired items. The guidance tool for consumers will be developed alongside roughly 1000 citizens, participating in a large-scale, transnational citizen-science project aimed at monitoring their problem-solving behaviour and identifying barriers to repair. At least 100 designers, from across the participating countries, will assist with developing the tool for 3D-printing designs. To sustain the digital infrastructure beyond the project lifetime, the partners will seek to develop a viable business model, notably by developing complementary physical infrastructure (Urban Resource Centres - URC) in the partner cities. These and other pilot actions will entail investments in personnel, software development, and equipment, among other things.

VITO's role

Together with KUL, VITO is responsible for estimating the environmental benefits due to upscaled repair activities. Two key activities are put forward:

- Improving impact measurement of the repair economy, both from a citizen perspective (total societal costs and benefits) and city perspective (impact on waste flows) compared to the baseline that will be established at the start of the project.

- Measurement of the environmental impact of repair will be improved by developing new metrics for impact measurement. The developed metrics will act as a guide for steering decision processes.

Project partners

- Maison du développement durable – Ottignies-Louvain-la-Neuve

- Gemeente Apeldoorn

- Stad Roeselare

- The Restart Project

- Repair&Share

- Delft University of Technology

- The Manchester Metropolitan University

- National University of Ireland Galway

- Association des Consommateurs Test-Achats

- Prototyping Collective

- Statik

- KU Leuven – Katholieke Universiteit Leuven

- Repair Together

- VITO

- Maakbaar Leuven

“Recycling the strongest metals” is the title of the animated TARANTULA project presentation movie. Researchers Seftel Elena Mihaela (VITO) and Martina Orefice (KU Leuven) explain the concept of the TARANTULA project, which aims at the recovery of tungsten, niobium and tantalum occurring as by-products in mining and processing waste streams.

How paper beach flowers made VITO / Vlakwa expert Dirk Halet look at our water system differently.

BioRECO2VER: biological routes for CO2 conversion into chemical building blocks

VITO's role

VITO is project coordinator. It studies microbial CO2 conversions through high pressure fermentation and bio-electrochemistry, performs validation testing on real industrial offgases and is involved in the techno-economic and sustainability assessment.

Project partners

Abstract

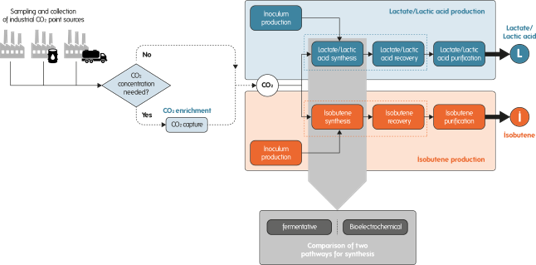

BioRECO2VER aims to demonstrate the technical feasibility of more sustainable non-photosynthetic biotechnological processes for the capture and conversion of CO2 from industrial point sources like refineries and cement production plants into valuable platform chemicals, i.e. isobutene and lactate. To overcome several of the existing technical and economic barriers for CO2 conversion by industrial biotechnology, BioRECO2VER will focus on minimizing gas pre-treatment costs, maximizing gas transfer in bioreactors, preventing product inhibition, minimizing product recovery costs, reducing footprint and improving scalability. To this end, a hybrid enzymatic process will be investigated for CO2 capture from industrial point sources and conversion of captured CO2 into the targeted end-products will be realized through three different proprietary microbial platforms which are representative of a much wider range of products and applications. Bioprocess development and optimization will occur along two lines: fermentation and bio-electrochemical systems. To prepare for industrial implementation and contribute to public acceptance, the technological activities will be complemented with virtual plant design, economic and sustainability assessments and extensive dissemination.

Om de opbrengst van landbouwgewassen te doen stijgen, is het noodzakelijk om de uitwendige kenmerken van planten nauwlettend op te volgen. Alleen zo kunnen experimentele gewasvariëteiten of behandelingsmethoden optimaal beoordeeld en geselecteerd worden. Tot nog toe gebeurde dat manueel. Suikerbietenzaadbedrijf SESVanderHave zet nu, via een strategische samenwerking met VITO, remote sensing in. Jürgen Decloedt (VITO) en Maarten Vanderstukken (SESVanderHave) leggen uit waarom deze manier veel efficiënter is en de basis kan zijn van grootse innovaties.

How do you reconcile the quality of life in cities with effective and efficient waste collection?

The importance of a circular economy should not be underestimated when making the transition to a low-carbon society. More than half of our CO2 emissions come (directly or indirectly) from the materials we use. The production of building materials is particularly notorious for the major impact it has on the climate. Earlier this year, VITO signed the Green Deal on Circular Construction, a commitment to support the transition to a world of circular construction in Flanders.

The demand for rechargeable batteries rises every day. The market is expected to quadruple over the next 10 years.

Together with 230 other participating public and private organisations, VITO kicked off the Green Deal Circular Construction on 22 February. VITO signs this Green Deal as OnePlanet@VITO to formulate its own commitment to support the transition to a circular construction sector in Flanders.

The EEA report ‘‘Trends and projections in Europe 2019 - Tracking progress towards Europe’s climate and energy targets’ presents an analysis of the EU progress towards the 2020 and 2030 targets for climate and energy.